Vinyltoluene stands as a proven alternative to styrene and has made waves since its first industrial applications around the 1940s. Back then, material chemists worked with limited tools, aiming to boost polymer durability without the drawbacks linked to existing monomers. During World War II, demand for synthetic resins spiked, and vinyltoluene filled a critical gap. The molecule’s ability to perform under various manufacturing conditions allowed designers and engineers to experiment with new formulations for paints, resins, and copolymers. The first commercial grades hit the market soon after, driven by industry giants looking to produce high-gloss coatings that stood up to wear and tear. Since those days, vinyltoluene gained a loyal following among resin producers who valued greater color stability and lower volatility than styrene.

In today’s world, most vinyltoluene finds its way into coatings, adhesives, and improved polystyrene substitutes. The liquid monomer typically arrives as a colorless or slightly yellow transparent substance, shipped in drums or bulk tankers. It brings more than just an alternative to the table — it delivers tangible improvements for all sorts of end products. Many resin formulators favor vinyltoluene for reducing yellowing, especially when sunlight or heat exposure threaten appearance and function. Producers blend it as a co-monomer to fine-tune hardness, drying speed, and flexibility in materials that line floors, cars, electronics, and even sports gear.

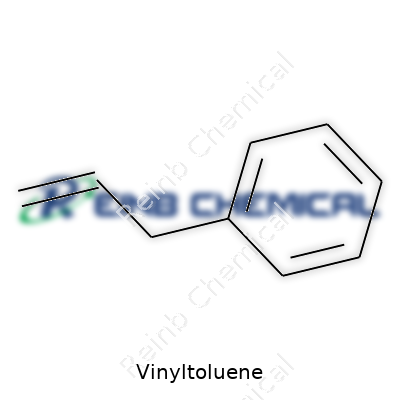

Vinyltoluene offers a distinctive scent, alongside a boiling point around 167°C and a density near 0.9 g/cm³. It stays fluid and clear under typical storage, but quickly reacts with oxygen and light, so handlers often add stabilizers for safer travel and longer shelf life. This monomer dissolves well in organic solvents, fitting naturally into most resin mixes. The molecule resists hydrolysis, an edge over styrene in humid or alkaline environments. Despite sharing similarities with styrene, the methyl substitution on the benzene ring alters reactivity and final product color stability, making vinyltoluene a valued special ingredient for anyone mixing custom batch blends.

Manufacturers rely on precise specs to keep batches consistent. Industry grades typically guarantee 98% purity or higher, with moisture content kept under 0.05%. The isomer distribution — mainly 3- and 4-vinyltoluene — gets spelled out clearly on documentation for regulatory and customer transparency. Every shipment bears clear hazard markings in line with UN regulations, as vinyltoluene classifies as a flammable liquid. Each label gives chemical formula C9H10 and proper shipping name, including identification codes recognized worldwide. Safety data follows GHS labeling practices; producers and shippers keep extensive records for compliance and emergency response.

Industrial-scale vinyltoluene production tends to follow a straightforward alkylation path. Toluene gets alkylated with ethylene via Friedel-Crafts conditions, using strong Lewis acid catalysts such as aluminum chloride. Reaction controls temperature and feed rate to steer toward the desired isomer mix. One key step many miss involves post-reaction purification through distillation to isolate the monomer and filter out unreacted material or trace byproducts. Purity matters — even small impurities can affect resin curing down the line, putting pressure on producers to refine every ton.

Polymer chemists appreciate vinyltoluene’s readiness for free-radical polymerization; it interacts smoothly with initiators like benzoyl peroxide. Adding it to typical styrene resins changes structure and end use properties, without reinventing the process line. Researchers use it to improve UV resistance and energy absorption in specialty plastics. Further modifications draw from the double bond and methyl group on the aromatic ring; functionalized vinyltoluene derivatives show promise in adhesives that demand strong bonds but need tunable flexibility. In the lab, vinyltoluene serves as a starting point for new hybrid monomers, and the groundwork here starts with the classic reactions, such as copolymerization with acrylates or maleic anhydride for specialized material science projects.

Across markets and catalogs, vinyltoluene shows up under various names: methylstyrene, methylstyrol, or under trade names attached to specific resin or coating system brands. Some lists split the product by isomer — meta- (3-) or para- (4-vinyltoluene) — but most resin producers lump these together as “vinyltoluene” and focus on isomer ratios for recipe accuracy. The global regulatory landscape encourages harmonized naming, especially as supply chains cross borders and more companies seek out lower-styrene alternatives for production.

Long experience teaches the importance of robust safety guidelines around vinyltoluene. Its flammability demands proper ventilation, spark-proof equipment, and rigorous handling training for every worker on the floor. Breathing in vapors or skin contact can cause irritation, and the monomer shows moderate acute toxicity. Every site using vinyltoluene builds out ventilation and spill response plans, and PPE ranges from goggles to full-face respirators, depending on process design. Safety audits review storage — drums kept out of sunlight, far from ignition sources — and OSHA or REACH regulations cover workplace exposure, labeling, and risk assessment. Industry groups push for continuous improvement in ventilation and monitoring, drawing from case histories and new research on health impacts.

Vinyltoluene’s main game is in specialty coatings, where it outperforms traditional resins under heat and UV stress. Floor finishes show fewer marks and slow down yellowing from daily foot traffic or sunlight. Industrial paints based on these resins land on bridges, stadium seats, and farm equipment, where every hour of protection counts. Electrical castings need low-loss properties for insulation — here vinyltoluene-based resins step in where ordinary polystyrene falls short. Adhesive formulators use the monomer for bonding metal and polymer without losing flexibility on assembly lines. Over the past twenty years, even sporting goods—from golf balls to hockey pucks—have benefited from vinyltoluene’s toughness and color retention.

Scientists continue to press vinyltoluene into new frontiers, aiming for better polymers with lower environmental footprint. University labs look at bio-based routes for synthesis, cutting out crude oil feedstocks. Material researchers design novel co-monomer blends for 3D printing filaments and biodegradable electronics. Industry consortia fund long-term weathering trials, testing new recipes under real-world exposure to rain, sun, and chemicals. Advanced analytics and high-throughput screening let teams study molecular behavior in ways the first vinyltoluene makers could only dream about. With growing attention on microplastic pollution, some projects explore degradability and recyclability options, weighing practical trade-offs between stability and responsible waste management.

Toxicologists have sized up vinyltoluene’s health risks through animal studies, occupational exposure surveys, and in vitro models for decades. Inhalation risks concern most workplace health programs, though chronic effects appear less threatening than those linked to older aromatic hydrocarbons. The skin irritation hazard keeps gloves and long sleeves in favor wherever the liquid flows. Environmental scientists pay close attention to water and soil run-off, advocating containment and treatment of all spent streams. Regulators keep data updated, and the industry faces growing calls to expand biomonitoring and fine-tune limits on worker exposure, especially in regions lacking robust chemical safety infrastructure. Real transparency and shared reporting remain key to making smarter safety decisions.

Trends in manufacturing, sustainability, and worker safety continue to shape vinyltoluene’s future. As styrene faces pressure due to volatility and health claims, alternative monomers gain ground for new resin blends. The rise in low-odor paints, specialty adhesives, and high-demand electrical insulators creates fresh markets for vinyltoluene derivatives. Collaboration between universities, industry groups, and regulatory bodies helps push green chemistry goals, sharpening focus on cradle-to-grave impacts. Newer synthesis pathways cut waste and energy use, promising more efficient and cleaner output. As end users and communities demand safer work environments and greener products, vinyltoluene producers find themselves balancing traditional performance with the shift toward sustainable innovation, setting the stage for the next chapter in polymer science and manufacturing.

Vinyltoluene shows up across a lot of industries, sometimes quietly, but always reliably. In the coatings field, I remember visiting a small furniture workshop that had barrels of resin stacked in a corner. The guys there didn’t look for the fanciest materials, only what worked—something that dried hard, stuck well, and didn’t let moisture in. Vinyltoluene was on their inventory list. It goes into making resins for coatings and paints that need to hold up for years, especially on wood and metal.

The chemical structure lets it blend well into alkyd and acrylic resins, making paints less likely to crack and chip. If you’ve ever put together patio furniture and noticed the finish lasts season after season, there’s probably some vinyltoluene behind that toughness. According to Dow and BASF, vinyltoluene-based coatings reach a good balance of flexibility and resistance to weather, which really matters for outdoor surfaces.

Vinyltoluene plays a big part in plastics, especially where clear optical quality or electrical insulation matters. I once visited a plastics plant and saw a whole section dedicated to polystyrene production. Most people don’t connect vinyltoluene to everyday objects, but it’s a key monomer there—a building block for certain plastics like plastic light covers, switchplates, and even drinking glasses that need to hold up without clouding or getting brittle quickly.

In electronics, insulators and encapsulations use vinyltoluene. The benefit here is quite direct: the plastics resist heat and block electricity. This means circuit boards have less risk of shorting out, even as devices get smaller and more packed inside. The global electronics industry, which moves billions of devices a year, relies on consistent quality in small things like this.

One use that surprised me came from a neighbor who worked in a hospital lab. Vinyltoluene-based scintillators show up in detectors for medical imaging and in research. These detectors catch and measure radiation. The purity of vinyltoluene and the way it forms clear, fast-responding materials make for quicker, more reliable readings in PET scans or environmental tests. Labs trust the stuff, and the science depends on that consistency.

Of course, every major chemical brings questions about safety and health. Workers making or using vinyltoluene need good ventilation, gloves, and eye protection. The EPA keeps tabs on its emissions, since breathing high levels might cause headaches or irritation. Strict rules on handling waste mean spills get cleaned up right away, not dumped down the drain.

Looking ahead, the conversation in chemical manufacturing always runs back to sustainability. Companies like Evonik and Eastman push for greener synthesis routes, recycling, and better containment. These steps matter, since the world can’t afford shortcuts with worker health or pollution. I’ve seen community watchdog groups stay active around chemical plants, reminding everyone that progress needs open communication and trust.

Professionals look to vinyltoluene because it earns its spot on the shelf—by making things stronger, clearer, and more durable. From the desk in a school classroom to a particle detector in a hospital basement, its uses might seem invisible, but the results are everywhere. If a challenge does come up, people in the field start with the basics: better training, clear labeling, and safer handling. It’s not excitement or flash; it’s doing things well, and that’s what keeps homes brighter, electronics safer, and science moving forward.

Vinyltoluene shows up in the world as C9H10. On the surface, that sequence looks as dry as any ingredient list. But if you’re working in construction, painting, or electronics, the mix behind those numbers holds real weight. C9H10 isn’t just a label—it directly ties into how safe, stable, and versatile a material will be once it’s out of the lab and into your workshop, plant, or product.

This compound sometimes wears the name methylstyrene. Its formula means it contains nine carbon atoms and ten hydrogens. You get one of three isomers, most often meta- or para-vinyltoluene, depending on which carbon the vinyl group attaches to on the toluene ring. That detail doesn’t just fill textbooks; it shapes how the chemical reacts with others and how well it performs once it lands in a factory setting.

From my own projects, handling vinyltoluene feels a lot like working with styrene, another well-known material, except with a bit more heft in how it resists yellowing and breaking down when exposed to light. That little bonus comes directly from the extra carbon ring in its structure. Manufacturers take advantage of this for plastics and protective coatings you trust to last, whether in tools or home surfaces.

The reasons for its popularity run deep. Vinyltoluene goes into resins, lacquer coatings, and specialty polymers, areas where you need predictable strength and shine. Polystyrene, for comparison, carries a formula of C8H8. By tacking on that additional methyl group, manufacturers improve heat resistance and flexibility. These changes may sound minor, but they let product designers stretch just a little farther, from better floor coatings to hard-wearing insulation foam.

Look at paints, for example. Add vinyltoluene and you can slow yellowing under harsh sunlight, cut down on cracks, and help surfaces survive extreme swings in temperature. Each time new regulations push for safer, cleaner alternatives, knowing the nuts and bolts behind formulas like C9H10 matters even more.

Chemical formulas aren’t just academic. Real risks tag along with vinyltoluene, especially during storage and transport. The odor, flammability, and potential fumes make careful handling a top priority for anyone on the shop floor. The U.S. Environmental Protection Agency (EPA) lists it as a hazardous air pollutant, flagging the need for good ventilation and solid personal protective equipment. Even so, I’ve seen workplace accidents traced to a lack of respect for these hazards, proving that knowing the formula isn’t enough—you must know what it really brings with it.

The big challenge kicks in where regulations and proper labeling meet real-world action. Encouraging routine safety audits and giving workers open access to safety data sheets can reduce risk. And there’s room for improvement in public databases, too—updating databases and enforcing better chemical tracking helps prevent costly mistakes. Responsible sourcing, clear labeling, and investment in green alternatives are key steps toward safer, smarter materials across industries.

Getting familiar with formulas like C9H10 pays off, not as a trivia question, but as a decision-making tool for anyone from safety managers to curious homeowners. The numbers and letters may look plain, but they anchor serious choices that affect safety, performance, and the environment.

Everyday objects like paints, coatings, and plastic composites wouldn’t be the same without certain chemicals working quietly behind the scenes. Vinyltoluene is one example. Manufacturers rely on it for making specialty plastics and resins, and I’ve seen it show up in workplaces that handle adhesives, lacquers, and electrical insulation. The debate turns serious once you consider whether this industrial helper creates health risks for the people breathing or working around it.

Vinyltoluene doesn’t belong in consumer products where kids or families will touch or swallow it. The real exposure problem comes in industrial or lab settings. During my visits to industrial paint and plastic workshops, workers risk inhaling its vapor or getting it on bare skin. If a ventilation system stalls out, or someone skips the gloves, the chances for trouble climb quickly.

Most folks don’t realize it, but strong organic chemicals often carry direct impacts on our bodies. Vinyltoluene vapor irritates the nose, throat, and eyes. I’ve met workers who picked up headaches, dizziness, or nausea within an hour of breathing in too much. One man described his workday ending in a fog he struggled to shake off for hours afterward. While most symptoms fade if you escape the fumes, the discomfort can easily throw off job performance—plus, nobody wants to end their shift feeling sick.

Chronic exposure makes the biggest difference. Breathing in moderate amounts week after week might hamper liver and kidney health, based on animal studies reviewed by government agencies like the National Institute for Occupational Safety and Health (NIOSH). There’s talk among health professionals about potential links to nerve problems in workers reporting memory lapses or concentration issues over several months or years. Scientists haven’t proven a strong cancer link in people, but evidence from similar chemicals pushes companies toward caution—especially because uncontrolled chemical exposure keeps adding up over time.

Companies and workers cut exposure by improving ventilation, using fume hoods, and following personal protective equipment protocols. From what I’ve seen in manufacturing plants, fit-tested respirators and well-fitting gloves offer the best day-to-day shield. I always advise break rooms far from production areas and simple changes of clothes at the end of a shift. These practical steps trim down the odds of tracking contaminants home, protecting children and family members.

No one signs up for a job expecting an invisible threat. Chemical health risks often simmer beneath the surface until somebody gets sick or raises a red flag. A strong safety culture begins with accurate training and clear information about chemical hazards like vinyltoluene. I encourage those managing worksites to swap stories, compare safety records, and never let short-term convenience trump long-term health. Public health watchdogs—OSHA, CDC, EPA—keep updating their advice so that our factories and labs don’t become sources of harm for the people on the ground. Open conversations and proactive planning make the biggest difference in staying safe.

Having worked near warehouses and plants, I’ve seen chemicals like vinyltoluene get overlooked. Many think a drum on a shelf is harmless until it leaks or reacts. Vinyltoluene brings specific risks: it’s flammable, gives off unpleasant vapors, and can break down if left unattended in sunlight or heat. Some users shrug off these risks, but taking shortcuts leads to real injuries and costly cleanup.

Take temperature. Vinyltoluene starts acting up if it’s left above 30°C for long stretches. Heat brings up its vapor pressure and kicks off unwanted reactions. The polymerization process might not look dramatic—until containers swell or rupture. A cool, dark, dry area keeps things stable. Warehouses with open windows let sunlight pour in and warm up the barrels, which spells trouble fast. Using temperature sensors and alarms doesn’t take much effort yet can prevent a warehouse emergency.

Anyone who’s witnessed a small shop fire knows the chaos a single spark can unleash, especially near volatile liquids. Vinyltoluene’s flash point sits low enough that open flames, static electricity, hot tools, or even faulty wiring pose real threats—no need for elaborate disaster scenarios. Metal drums must be grounded when transferring the liquid. Non-sparking tools, fume hoods, and proper signage all help. Regular fire drills and checks mean staff won’t freeze up during an actual event. Safety data sheets spell out recommended extinguishers—typically foam or powder. Water only spreads the mess.

Whenever I’ve watched new hires try to rush through handling drums, I spot open skin and cheap gloves. Vinyltoluene can irritate skin and eyes, and breathing in its vapors brings headaches and even dizziness. Goggles, chemical-resistant gloves, and fitted masks aren’t extras—they’re basic gear. Clean clothing and eye-wash stations need to be close by. Spills should get mopped up using absorbent, non-combustible material. Labels on storage drums should never fade or peel. Mixing up vinyltoluene with a more stable chemical guarantees trouble.

In storage, vinyltoluene wants an inhibitor, usually something like t-butylcatechol. Skipping this step, waiting too long between shipments, or not rotating inventory leads to thickening and clogs. If containers smell off or the liquid looks cloudy, disposal must follow strict chemical waste protocols. Regular checks on storage life matter just as much as any regulatory rule—compromised vinyltoluene has cost several businesses hefty fines.

No chemical safety program runs on paperwork alone. Ongoing training helps every worker spot a bad situation before it happens. If a record shows a shipment sat too long in a humid corner, a supervisor can step in. Digital logs, clear incident reports, and visible safety instructions offer more value than dusty binders. Good practices aren’t just for audits—they keep real people safe.

Simple fixes can go a long way: automatic sprinklers, extra ventilation, tighter access controls. Separating incompatible chemicals (like oxidizers) in storage avoids surprise reactions. Regular maintenance, with clear checklists, keeps systems ready. Working with experienced logistics partners and hazardous material handlers pays off in both safety and insurance costs.

In the end, preventing accidents means creating a culture where no one treats safety as a formality. Vinyltoluene brings unique storage and handling needs. Paying close attention and following best practices do more than just tick boxes—they protect workers, assets, and the surrounding community.

Vinyltoluene stands out in the world of chemistry thanks to its mix of properties, and I’ve seen plenty of folks focus only on the numbers without thinking about why they count. Vinyltoluene looks like a clear liquid, and if you open a container, the strong, sweet smell rises up right away. That’s not just a random detail. The scent hints that it’s volatile. With a boiling point just under 170°C, you won’t have to crank up the heat much to watch it move off as vapor. Industrial plants often need to keep it sealed tight, because letting it hang around in the air isn’t just a nuisance — it means losing valuable material and creating potential hazards.

If you spill vinyltoluene, it flows quickly: the viscosity is pretty low, almost like water, so you aren’t going to see it behaving like a syrup or oil. Spills tend to spread. That makes cleanup urgent and helps explain why storage always comes with spill kits nearby. Density clocks in at about 0.91 grams per cubic centimeter. Pour it on water and it’ll float every time, which can complicate water cleanups and calls for absorbent pads built for floating solvents.

For anyone working with vinyltoluene in a factory setting, flash point matters—roughly 49°C means it catches fire from a pretty low heat source. Someone absent-minded with a heat gun or even a strong bulb could trigger a fire. This kind of risk stays with me: fire risk gets real fast when you deal with chemicals that vape off or ignite at these temperatures. So you find strict temperature controls anytime vinyltoluene is part of a process.

One thing that makes vinyltoluene handy is its ability to remain stable under room temperature and pressure. But once you start mixing it with acids or bases, or pumping it under strong UV lights, it doesn’t just sit there. It can kick into polymerization unexpectedly. Factories will often add stabilizers to the barrels specifically for this reason, trying to prevent runaway reactions. This safety habit isn’t just box-ticking for insurance.

Whenever someone in the lab picks vinyltoluene over something else, they don’t do it on theory alone. Immiscibility with water is one thing. If you try to wash it away with water, it won’t mix—the droplets stay separate, which hints at the need for specific solvents for cleaning and preparation. Vinyltoluene also blends smoothly with a lot of organic materials. That's a reason paint and adhesive makers like it: you’re not going to get strange textures or weird separation as long as it’s handled right.

These direct physical details all affect choices on the factory floor. Workers think about how easy it is to pump or stir, how quickly it might evaporate and bump up exposure risk, and what happens if it escapes into water. Solutions start with real training. People handling vinyltoluene always need to lean into proper storage practices, wearing gloves made of the right material, and understanding that regular ventilation isn’t just a guideline—it's non-negotiable. Education, not just rules, makes safe habits stick, and that’s where the real answer to handling tricky chemicals starts.

| Names | |

| Preferred IUPAC name | 1-Ethenyl-4-methylbenzene |

| Other names |

Methylstyrene Vinylmethylbenzene Methylphenylethylene |

| Pronunciation | /ˈvɪnɪlˈtɒljuːiːn/ |

| Identifiers | |

| CAS Number | 25013-15-4 |

| Beilstein Reference | 1341196 |

| ChEBI | CHEBI:28659 |

| ChEMBL | CHEMBL228127 |

| ChemSpider | 12173 |

| DrugBank | DB14096 |

| ECHA InfoCard | 100.011.009 |

| EC Number | 202-433-2 |

| Gmelin Reference | 6931 |

| KEGG | C01725 |

| MeSH | D014738 |

| PubChem CID | 7498 |

| RTECS number | XN8225000 |

| UNII | W6G4K2I5K6 |

| UN number | 1307 |

| Properties | |

| Chemical formula | C9H10 |

| Molar mass | 132.20 g/mol |

| Appearance | Colorless liquid |

| Odor | Aromatic odor |

| Density | 0.960 g/cm3 |

| Solubility in water | insoluble |

| log P | 3.5 |

| Vapor pressure | 0.5 mmHg (20°C) |

| Acidity (pKa) | 44.9 |

| Basicity (pKb) | 11.2 |

| Magnetic susceptibility (χ) | -8.4e-6 |

| Refractive index (nD) | 1.5450 |

| Viscosity | 10 mPa·s at 25°C |

| Dipole moment | 0.67 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 364.8 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | 97.76 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -4677.9 kJ/mol |

| Pharmacology | |

| ATC code | C05CA04 |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H226, H315, H319, H335 |

| Precautionary statements | P210, P261, P280, P305+P351+P338, P403+P235, P501 |

| NFPA 704 (fire diamond) | 2-3-2 |

| Flash point | 54 °C (129 °F) |

| Autoignition temperature | 490 °C |

| Explosive limits | 1.1–6.4% |

| Lethal dose or concentration | LD50 (oral, rat): 5,000 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat 5,000 mg/kg |

| NIOSH | WX8225000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) of Vinyltoluene is "100 ppm (480 mg/m3) |

| REL (Recommended) | 200 ppm |

| IDLH (Immediate danger) | 500 ppm |

| Related compounds | |

| Related compounds |

Styrene Divinylbenzene Butylated hydroxytoluene Ethylbenzene |