p-Diethylbenzene started getting attention in the early days of the petrochemical industry. Chemists who searched for efficient solvents and base chemicals began isolating aromatic hydrocarbons from coal tar and refining petroleum. By the middle of the twentieth century, engineers found efficient methods to separate it from related compounds, mainly through catalytic reforming and distillation processes. Researchers in materials science started looking at its properties and the ways it could boost performance in chemical manufacturing, particularly as chemicals became tightly woven into agriculture, plastics, and synthetic fibers.

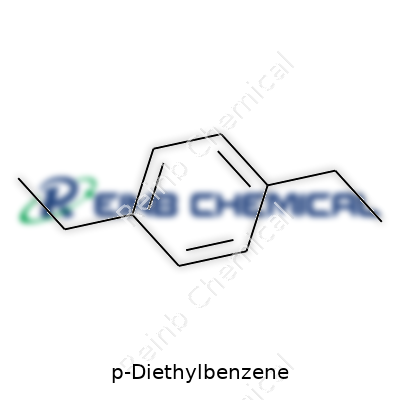

p-Diethylbenzene belongs to the family of ethyl-substituted benzenes. Its structure features two ethyl groups linked to a benzene ring in the para position, making it less reactive on the surface but surprisingly useful in a range of processes. Commercial grades usually aim for high purities, serving sectors like specialty solvents, resin production, and fine chemical synthesis. The demand for p-Diethylbenzene reflects not just its own value, but its place as a starting material for further chemical transformations that ultimately end up in common products people use every day.

This compound stands out with a melting point around -25°C and a boiling point that hovers close to 184°C. It appears as a clear, colorless liquid under normal conditions, carrying a mild aromatic odor. With a formula of C10H14 and a molecular weight just over 134 g/mol, p-Diethylbenzene dissolves well in organic solvents like ether and benzene but resists mixing with water. Chemically, it’s stable at room temperature, but degrades under strong oxidation or halogenation. These properties make p-Diethylbenzene easy to store, but caution remains necessary because of its volatility and flammability—risks that get addressed directly in plant safety protocols.

Chemicals of this grade reach the market under strict specs: purity above 99%, water content below 0.1%, and limited levels of meta- and ortho-isomers. Packaging often comes in steel drums or high-density polyethylene containers to keep contamination out and evaporation at bay. Manufacturers and shippers must label containers according to local and international guidelines—hazard codes, UN numbers, and emergency advice lines all show up in big bold print. Every transfer or use goes with material safety data sheets and compliance checks, especially in the European Union and North America where chemical audits face no room for shortcuts.

Industrial setups use either alkylation or transalkylation reactions, typically leveraging catalysts such as aluminum chloride or zeolites. For alkylation, benzene meets ethylene under controlled temperatures and pressures, producing mixtures of mono-, di-, and tri-ethylbenzenes. Manufacturers prefer para-selectivity, so reactors get optimized to favor formation of the target isomer, sometimes using shape-selective zeolites that restrict access to certain positions on the aromatic ring. Afterward, separation processes like distillation isolate p-Diethylbenzene with high purity before moving it to storage or further modification.

Although less reactive than some aromatics, p-Diethylbenzene can undergo oxidation to yield para-diethylbenzene diacid or para-diethylbenzene diol, both of which open doors to specialty polymers and plasticizers. Friedel-Crafts reactions introduce functional groups that tailor the molecule for advanced material design, including specialty resins and fuel additives. Changing one or both ethyl groups unlocks new derivates, expanding options for downstream users. Each step gets measured carefully to ensure no side-reactions waste material or spike the byproduct load, a concern that grows as environmental standards tighten.

This molecule appears in registries under names like 1,4-Diethylbenzene, p-Diethylbenzol, and para-Diethylbenzene. It gets cataloged across chemical databases and supplier catalogs with its CAS number and international chemical identifiers. These synonyms help buyers, regulators, and researchers keep track of the compound across borders and language barriers. Knowing every alias proves important in regulatory checks and in sourcing alternatives during supply chain bottlenecks.

The low flash point and inhalation risks of p-Diethylbenzene push plant managers to run strict controls on handling and storage. Proper personal protective equipment like gloves, goggles, and flame-resistant clothing becomes standard gear wherever open containers appear. Ventilation systems, explosion-proof lighting, and vapor detection monitors all get routine checks, as do spill containment kits and emergency response plans. Exposure limits get highlighted in operational rules to keep those involved safe from both acute effects like dizziness and longer-term risks such as liver or kidney stress. Transportation regulations, especially for export, force shippers to track documentation closely and use certified containers that don’t leak or degrade on long routes.

Most p-Diethylbenzene ends up as a precursor to advanced chemicals used in plastics, antioxidants, and lubricants. Resin producers count on it when they manufacture ion-exchange materials, particularly as demand for ultrapure water and air grows in electronics and food processing. It shows up in surfactants, cold-weather solvents, and chemical standards for chromatography. Specialty labs draw on its stable ring structure for experimental syntheses, giving rise to pigments with improved weather resistance and plasticizers that outperform traditional phthalates. In some fields, custom treatments convert it into specialty epoxides or fine fragrances for use in high-end cosmetics.

Scientists dig into process efficiency, greener synthesis methods, and new applications for p-Diethylbenzene. Zeolite catalysts keep improving, reducing unwanted side-products and slashing waste. Research teams at universities and chemical companies push into catalysis, aiming for cleaner transalkylation and even direct photo- or electrochemical routes. Computational chemists look for pathways that might lower energy costs or increase selectivity, promising savings for manufacturers who need to stretch budgets and lower emissions. Meanwhile, lab-scale investigations try out new reactions to convert this base molecule into next-gen polymers and biodegradable agents, showing real movement towards sustainability goals.

Interest in p-Diethylbenzene’s health impact isn’t just academic. Early animal studies pointed to moderate acute toxicity, mainly through respiratory and digestive routes. Chronic exposure brought concerns when liver and kidney parameters changed after long-term dosing. Industry health experts keep monitoring updates to exposure guidelines, drawing on evidence from both lab animals and factory workers. Regulations set strict limits to keep average airborne concentrations in check. Despite its wide use in industry, p-Diethylbenzene doesn’t often pop up in consumer products, partly because of these health flags, and that trend looks set to continue as tighter chemical management standards roll out across developed economies. Real-time exposure detection and better containment gear now form the backbone of modern factory safety.

As countries invest in advanced materials and green chemistry, p-Diethylbenzene will stay on procurement lists for specialty chemicals. Research promises new catalytic approaches that shrink carbon footprints and cut feedstock waste. Ongoing work in polymer chemistry may open new applications in lightweight composites, filtration membranes, or custom adhesives tailored for a circular economy. If recycling and chemical recovery systems become mainstream, downstream users may reprocess byproducts containing ethylbenzenes, turning today’s offcuts into tomorrow’s supply flows. The steady push toward higher safety, tighter emissions controls, and smarter supply chains will keep shaping how p-Diethylbenzene fits the bigger industrial story.

Many people have never heard of p-Diethylbenzene, but it plays a subtle role in everyday products and processes. From synthetic resins to specialty solvents, this compound finds its way into a surprising number of corners. Chemists and manufacturers pay attention to it, not just for its properties, but for what it makes possible down the line.

Production plants count on p-Diethylbenzene—often referred to in the lab as PDEB—mostly as a precursor to other chemicals. The biggest story centers on its use in creating diethylbenzene derivatives, which form the backbone of some specialty polymers. For example, PDEB undergoes further processing to yield certain isomers, with para-xylene and meta-xylene being just two relatives in the family. In my early chemistry days, I handled a lot of these aromatic hydrocarbons, always amazed how small tweaks in chemical structure changed where compounds ended up in industry.

Every year, refinery engineers process thousands of tons of aromatic hydrocarbons, and a portion of these streams contains PDEB. Manufacturers often separate it out to create unique resins, adhesives, or intermediates used in surfactants. The detergent industry leans on intermediates derived from PDEB to help break up greasy stains in laundry and dishwashing liquids.

Companies involved in plastics often turn to p-Diethylbenzene when they want to produce ion-exchange resins. These resins end up in water-softening and purification systems—think municipal treatment plants or even home water filters. A lot of people, myself included, care deeply about clean water, and every link in the purification chain needs stable, reliable materials. Ion-exchange resins depend on the robust aromatic rings found in compounds like PDEB; without them, we’d see more breakdowns and lower efficiency.

On another front, p-Diethylbenzene enters the mix as a solvent in laboratory and industrial environments. It doesn’t rank as the world’s most common solvent, but its chemical stability and low reactivity make it a smart pick for reactions that need a tough, non-polar medium. In my own experiments, I reached for PDEB when tackling syntheses with sensitive materials where common solvents would ruin the outcome.

Manufacturers handle p-Diethylbenzene with caution. It brings some risks—exposure can irritate the skin or respiratory tract, and large spills threaten soil and groundwater quality. Regulatory agencies, including the EPA and OSHA, pay close attention to how plants store and dispose of PDEB and related chemicals. In my years of working with aromatic hydrocarbons, proper training and good ventilation made a world of difference. Workers wear gloves, goggles, and use fume hoods religiously, which helps catch accidents before they snowball.

Some companies are now looking at ways to minimize waste and recycle aromatic compounds. Closed-loop systems allow recovery and purification of PDEB from process streams, saving money and cutting down emissions. Environmental groups push for greener alternatives, but so far, the unique chemistry of p-Diethylbenzene means there aren't many viable replacements.

Demand for p-Diethylbenzene ties directly into the health of the chemical and plastics industries. As consumer pressure grows for safer, cleaner materials, chemical engineers will need to keep finding better ways to work with and manage aromatic compounds. My own takeaway: progress in chemistry rarely happens in sweeping gestures. Usually, a compound like PDEB quietly supports countless important materials, shaping daily life in ways most people never notice.

p-Diethylbenzene brings something unique to the table when looking at aromatic hydrocarbons. Structurally, this molecule places its two ethyl groups opposite each other on a benzene ring — sometimes called the para-position. This small detail changes how it behaves and where it shows up in real life.

At room temperature, p-Diethylbenzene shows up as a colorless, oily liquid. Its boiling point lands around 183°C. That higher boiling point, compared to more volatile benzene relatives, comes from those two bulky ethyl groups. They make the molecules stick together a bit more, so heat has to work harder to break them apart. Melting happens near 9°C, which keeps it liquid under most work conditions.

You won't see it floating on water — with a density close to 0.87 g/cm³, it sinks lower than water but keeps up the lighter-than-water trend typical for many hydrocarbons. It hardly dissolves in water at all, fitting the stereotype for benzene derivatives. Introduce p-Diethylbenzene to organic solvents like ether or ethanol, though, and it blends right in. The smell stands out — strong, sweet, and noticeable, echoing other compounds in its family.

This compound holds on tight to its structure. The benzene ring, known for resisting most chemical attacks, remains stable even with the two ethyl groups. That stability means it does not break down easily under normal storage, helping industries avoid unpleasant surprises. But in the right setting, those same ethyl groups make the molecule more reactive than plain benzene — targeting them lets chemists build even bigger molecules.

Oxidation sticks out as a common reaction route. Under strong oxidizing conditions, each ethyl group changes into a carboxylic acid, turning the compound into terephthalic acid — a feedstock crucial for polyester production. That shift forms the basis for a huge slice of the plastics supply chain.

Industrial chemists use p-Diethylbenzene as an intermediate—a stepping stone to bigger, more complicated molecules. Refineries may bump into it during the alkylation of benzene. Beyond the raw materials, this compound can help grow specialty plastics, resins, and solvents. Its chemical makeup makes it a solid choice for controlled reactions in closed environments, limiting exposure to workers and the public.

Those handling p-Diethylbenzene need to stay alert, though. Even with its stability, it's a flammable liquid, so storage calls for well-ventilated spaces and fire controls. Protection — gloves, safety glasses, and good ventilation — goes a long way toward cutting health risks tied to inhaling vapors or direct contact with skin.

Personal experience counts for a lot in the chemical world. A mistaken spill or lax attitude with p-Diethylbenzene can create headaches: vapor inhalation irritates the lungs, and skin exposure leads to dryness or rashes. Good training and practical safety habits matter more than any technical description.

Environmental groups track hydrocarbons like this closely. Spills can travel, sinking below water surfaces and resisting breakdown. Local governments and plant operators take extra care to prevent leaks and invest in cleanup systems that catch the compound before it spreads. Investing in closed-loop systems, process improvements, and worker training pays off, keeping both people and ecosystems out of harm’s way.

For industries aiming to shrink their carbon footprint, reevaluating process choices for solvents and intermediates stands as a real step forward. Research into greener alternatives and smarter handling can lower the risks without losing the benefits brought by this useful chemical.

p-Diethylbenzene comes up mostly in industrial plants. It’s a chemical people use in making plastics, resins, and even in some lab applications. I’ve come across it in a college organic chemistry lab—stored with a warning symbol and some strict handling rules. It never got the same limelight as benzene or toluene, but safety was never an afterthought with this compound.

Take a good look at the research on p-Diethylbenzene and the first thing that jumps out is its connection to respiratory problems. If someone inhales the vapor, irritation in the nose, throat, and lungs can show up fast. Inhalation at high concentrations can dizzy people, bring on headaches, or even cause loss of coordination. Liquid p-Diethylbenzene feels oily; skin exposure leads to redness and sometimes blisters, especially if that contact stretches over hours. Eyes react sharply too—pain, tears, and blurred vision stack up as common complaints in exposed workers. NIOSH and OSHA recommend firm exposure limits, and there’s a reason for that: long-term contact ramps up risk, not just for discomfort, but possible damage.

The story doesn’t end with skin and lung reactions. The body, especially the liver and kidneys, works hard to process this chemical. Scientists have recorded changes in organ tissue among rats when they tested longer exposures. There isn’t rock-solid proof of cancer risk, but similar benzene group chemicals have raised big alarms for leukemia and other diseases. Those who spend years in close quarters with the fumes or who clean up after industrial spills would do well to avoid dismissing that risk.

Now, take p-Diethylbenzene outside the lab and into streams, fields, or city drains. Small spills evaporate in open air, but enough of it seeps into soil or groundwater. Aquatic life doesn’t stand a chance if concentrations climb. Fish and insects handle a little bit, but a moderate leak triggers suffocation or death. Thanks to its slow breakdown, p-Diethylbenzene lingers in groundwater and can show up in drinking wells. Rural communities near industrial plants sometimes face long cleanups, and I’ve followed news about contaminated wells drag on for years. The EPA categorizes this chemical as hazardous for a reason—the risk to water fits the criteria for concern.

Luckily, p-Diethylbenzene isn’t as volatile as some chemicals, so you don’t see the fires or thick clouds that make headlines, yet that can work against prevention. Problems grow quietly, so they often don’t get caught right away. Workers sometimes don’t notice symptoms until the damage sets in. Nature deals with chemicals over generations, and the cost of cleanup always lands on towns and families nearby.

Reducing risks really comes down to smart handling. Proper ventilation, thick gloves, and goggles matter as much as the warning labels suggest. Companies using p-Diethylbenzene can invest in sealed systems to cut down leaks and run regular training sessions for everyone on the floor. Emergency plans for chemical spills, plus investment in sensors to catch vapor leaks, would go a long way. On a larger scale, tracking wastewater and air quality near industrial zones matters. It's not just about keeping operations running—it's about protecting current and future generations from a slow-building threat.

Walk through the world of organic chemistry, and p-diethylbenzene shows up as a workhorse. Maybe you’ve handled lab solvents. Maybe you see its uses in making antioxidants or specialty polymers. Behind that bottle is an intricate story. Unlike some commodities, p-diethylbenzene calls for a sharp understanding of organic reactions and controlling chemistry on an industrial scale.

The usual way to make p-diethylbenzene involves alkylation. Take benzene, toss in ethylene, fire up a catalyst — often aluminum chloride — and keep a careful eye on the temperature and pressure. It isn’t just chemistry in a beaker. You need the right equipment and a nose for handling strong acids and gases. Most plants use a vapor-phase process, pushing benzene and ethylene over a solid catalyst. This route helps dial in the “p-” orientation, which stands for the para-isomer, rather than ending up with unwanted byproducts.

Industrial processes have moved away from only using aluminum chloride, since that method created plenty of waste salts. Today, zeolite catalysts draw attention. They cut down on pollution, and they last longer before fouling. From my time in a small research group, I saw firsthand how tough it was to keep those zeolites working. Any stray sulfur or water in the feed could poison them, leading to reactor shutdowns, expensive cleanup, and wasted time.

The punchline in chemical manufacturing often hides in separation. The para (p-) form boils close to the ortho- and meta-isomers, making the purification a real chore. Fractional distillation comes into play, but efficiency is never perfect. Some makers take the crude mix and crack or isomerize the other isomers, driving them toward the para variant. This step keeps the yield high and shrinks waste. From a sustainability angle, reusing leftover byproducts like meta-diethylbenzene makes sense both for profits and the planet.

Handling benzene carries major health risks. Strict ventilation and quick cleanups are more than checkboxes on a safety list — they prevent cancer risks for workers. I remember a time in the pilot plant, with alarms blaring after a minor leak. Response times saved headaches, and the team doubled down on safety reviews after that.

Industry veterans push for greener approaches. Companies keep searching for catalysts that work at lower temperatures, last longer, and need less frequent replacement. Some labs in Europe experiment with less toxic feedstocks and try to recycle reactor heat and process wastes. While incremental, these steps add up over time, especially as environmental rules tighten. From my research days, chasing higher yields felt less valuable than finding a smarter way to handle leftovers or cut water use — moves that protect both workers and the broader environment.

The stakes run past profit margins. Products downstream from p-diethylbenzene show up in medical supplies, plastics, and additives. If cleaner processes can bring less risk, lower emissions, and protect the crew running these plants, it seems worth the investment. Progress rarely comes in leaps, but every improved reaction and safer plant layout brings chemistry a little closer to a responsible future — not just for those inside the factory, but for anyone counting on safe, reliable, life-enhancing products.

p-Diethylbenzene comes across as a colorless organic compound, found in chemical research and in the making of resins or specialty polymers. The stuff smells quite strong, and its vapors don’t make for a pleasant afternoon. Since many folks may not have crossed paths with this chemical, there’s a chance its risks creep up unnoticed unless you’ve had a safety briefing. Handling p-Diethylbenzene safely matters for the people working in research labs, factories, or even smaller operations where folks might use it as a solvent.

Inhaling the vapors acts as the main risk. A few deep breaths near an open container can leave you dizzy or lightheaded, with headaches showing up quickly. Getting this chemical on skin can lead to irritation, redness, or rashes. Long-term exposure can hurt your liver or kidneys since it builds up in the body over time. Eye contact stings and burns right away—vision blurs, and the pain lingers. None of this is theory. Chemists and plant technicians often tell stories about slip-ups that sent them home early, wishing they’d taken a minute longer to put on gloves or check the ventilation.

p-Diethylbenzene catches fire much easier than water boils. Some organic solvents wait for a flame, but this compound only needs a little spark or static discharge. Vapors drifting close to an ignition source can make an entire bench or work area explode into flames. Even small spills can spread vapors fast, filling a room with flammable air. I remember hearing about a late-night cleanup gone wrong in a college lab, where the exhaust fans had failed. The next morning, the air tested above the flammable limits, and nobody could enter for hours.

Anyone stepping up to a bottle of p-Diethylbenzene should wear the right chemical-resistant gloves, goggles, and a long-sleeve lab coat—or even a flame-retardant apron if things might get messy. Don’t count on ordinary latex gloves; you want nitrile or neoprene. Good ventilation wins over anything fancy. Fume hoods or filtered exhausts pull vapors away from your face. Keeping containers tightly closed stops accidental releases. Neatness forces good habits, so wiping down benches and labeling every bottle makes it easier for your coworkers to notice spills or mix-ups.

In my lab days, we always kept fire blankets and a working shower in reach, no exceptions. If a spill happened, the go-to method involved using inert absorbent material—no sawdust or paper towels, since they only soak up liquid, not fumes. Used pads go in sealed bags, then into hazardous waste bins. Folks working with larger quantities count on grounding and bonding for containers, to block static sparks while pouring or mixing.

Accidents demand quick action. Splash to the eyes? Get straight to an eyewash for a full rinse. Overcome by fumes? Step into fresh air fast and call for help. Fire means reaching for a CO2 or dry chemical extinguisher, never water, since the chemical floats and spreads fire faster. Making a checklist and rehearsing emergency drills mean everyone knows how to react before panic sets in or injuries pile up.

Culture shapes safety. Peer reminders, regular training, and real feedback keep everyone alert. I’ve seen places where a single careless splash caused weeks of disruption. Each new hire—even folks shadowing for a day—ought to walk through storage rules, disposal steps, and real-life case studies. The sense of responsibility builds as folks see the payoff: clean records, steady work, and peace of mind at the end of every shift.

| Names | |

| Preferred IUPAC name | 1,4-Diethylbenzene |

| Other names |

1,4-Diethylbenzene p-Diethylbenzol para-Diethylbenzene |

| Pronunciation | /ˌdiːˌɛθɪlˈbɛnziːn/ |

| Identifiers | |

| CAS Number | 105-05-5 |

| Beilstein Reference | 1209271 |

| ChEBI | CHEBI:15747 |

| ChEMBL | CHEMBL15970 |

| ChemSpider | 68188 |

| DrugBank | DB03027 |

| ECHA InfoCard | InChIKey=OSWPMRLSEDHDFF-UHFFFAOYSA-N |

| EC Number | 202-437-7 |

| Gmelin Reference | 71473 |

| KEGG | C07080 |

| MeSH | D003962 |

| PubChem CID | 8233 |

| RTECS number | DI8925000 |

| UNII | EC16H2O1I3F |

| UN number | UN2529 |

| CompTox Dashboard (EPA) | DTXSID9020441 |

| Properties | |

| Chemical formula | C10H14 |

| Molar mass | 134.22 g/mol |

| Appearance | Colorless liquid |

| Odor | aromatic |

| Density | 0.867 g/mL |

| Solubility in water | Insoluble |

| log P | 3.3 |

| Vapor pressure | 0.27 mmHg (25°C) |

| Acidity (pKa) | pKa ≈ 43 |

| Basicity (pKb) | 6.44 |

| Magnetic susceptibility (χ) | −71.0·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.4905 |

| Viscosity | 1.106 mPa·s (25 °C) |

| Dipole moment | 0.0 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 286.5 J/mol·K |

| Std enthalpy of formation (ΔfH⦵298) | -57.3 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -4566.0 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02, GHS07 |

| Signal word | Warning |

| Hazard statements | H226, H304, H315, H319, H335 |

| Precautionary statements | P210, P261, P273, P280, P301+P312, P304+P340, P305+P351+P338, P312, P330, P337+P313, P403+P235 |

| NFPA 704 (fire diamond) | 1-2-0 |

| Flash point | 62°C (closed cup) |

| Autoignition temperature | 432 °C |

| Explosive limits | 0.8–6.7% |

| Lethal dose or concentration | Lethal dose or concentration: LD50 (oral, rat): 3,230 mg/kg |

| LD50 (median dose) | LD50 (median dose): 4,330 mg/kg (rat, oral) |

| NIOSH | SN8750000 |

| PEL (Permissible) | PEL: 100 mg/m3 |

| REL (Recommended) | 5 ppm |

| IDLH (Immediate danger) | 750 ppm |

| Related compounds | |

| Related compounds |

Benzene o-Diethylbenzene m-Diethylbenzene Ethylbenzene Diisopropylbenzene Cumene |