Chemists first took serious interest in diisopropylbenzenes more than a century ago while exploring ways to modify the basic benzene ring for industrial use. Early work focused on production through Friedel-Crafts alkylation, which uses benzene and propylene in the presence of an aluminum chloride catalyst. m-Diisopropylbenzene, also known as 1,3-diisopropylbenzene, entered the spotlight during the growth of the petrochemical industry in the mid-20th century. Demand rose quickly as its usefulness became clear, particularly for making phenolic resins and additives. Researchers tracked how adjustment of reaction conditions—temperature, catalyst, pressure—affected yields for the different isomers. The 1,3-isomer gained a reputation for unique reactivity and became an interesting base compound for further chemical modification.

Industrial production of m-diisopropylbenzene occurs on massive scales, particularly in regions with mature refining operations. It presents itself as a clear, oily liquid with a distinct aromatic smell, finding regular purchase orders from chemical synthesis labs and specialty manufacturers. On the shelf, it typically arrives in steel drums or glass bottles, each carefully labeled with appropriate hazard warnings. Stakeholders across resins, plastics, and oil refining see it as a backbone chemical, anchoring a long list of manufacturing chains. Development teams in these fields count on stable, high-purity material with well-defined characteristics, as downstream quality rests on upstream control.

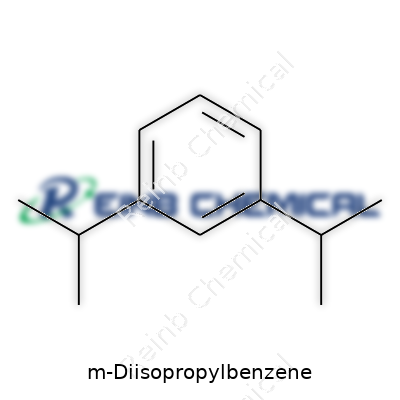

This compound boils at around 220°C and solidifies slightly below −50°C, giving it a robust liquid range suitable for industrial work. Its molecular formula is C12H18. Because of its aromatic ring, the molecule brings all the stubbornness and reactivity associated with substituted benzenes. It dissolves well in traditional organic solvents, such as toluene or hexane, but shows almost no miscibility with water. Its vapor can irritate the eyes and nose, so effective ventilation and gloves are not optional. From a technical point of view, the two isopropyl groups at the 1 and 3 positions set the compound apart from both the ortho- and para-isomers, leading to distinct behaviors in oxidation and further substitution.

Producers of m-diisopropylbenzene publish detailed technical sheets, spelling out its purity range—usually well above 98 percent—as well as content of moisture and trace by-products. The product usually comes with safety data sheets that list recommended storage temperatures, incompatibilities, and personal protective equipment. GHS-compliant labeling helps workers quickly identify flammable potential, health risks, and emergency spill responses. Chemical identification numbers, such as CAS 99-62-7, show up on every label, along with batch data to allow quick sourcing in traceability checks. Engineers and safety officers use this data every day to design their handling protocols.

Commercial plants rely on a straightforward Friedel–Crafts alkylation of benzene using excess propylene in the presence of aluminum chloride or zeolite catalysts. The challenge lies not in performing the reaction, but in tuning the catalyst and temperature to favor the meta product rather than its isomers. Certain modern routes use continuous reactors and manage heat closely to get the best yields while keeping energy costs under control. Laboratory-scale routes look similar, though smaller reactors with reflux condensers replace the hefty industrial vessels. The final product passes through careful distillation, stripping out unreacted starting materials and low-boiling impurities, until a steady stream of high-purity liquid fills the drums.

Chemists value m-diisopropylbenzene both for what it is and what can be made from it. Direct oxidation, using air and metal catalysts, leads to a range of dihydroxy derivatives, similar to how cumene yields phenol. These hydroperoxide intermediates catch the interest of those making epoxy resins and antioxidants. Nitration, sulfonation, and halogenation open up additional synthetic windows, often targeting new resins or intermediates for agrochemical work. Subtle electronic effects from the isopropyl groups guide substitutions to favored positions, allowing clever control over product distribution in multi-step syntheses.

Outside of m-diisopropylbenzene and 1,3-diisopropylbenzene, people sometimes call it m-DIPB or meta-diisopropylbenzene. Catalogs from chemical suppliers may group it under these labels, each tied to product numbers and inventory slots that labs reference for reordering. Older publications sometimes refer to it as the ‘meta’ derivative, but most modern users stick to the more precise descriptive names. Large-scale buyers and traders recognize the trade codes used by refineries, which keep procurement running smoothly across borders and registry systems.

Handling this compound demands respect for volatility and toxicity profiles. In poorly ventilated rooms, vapors can annoy the upper respiratory tract, and splashes to skin mean a risk of irritation or longer-term sensitization. Industrial sites design spill containment around drum storage areas and train staff in emergency decontamination. Eye protection, solvent-resistant gloves, and flame-retardant clothing form the baseline. Regulations set by OSHA, REACH, and local agencies guide maximum allowable exposures. Production and shipment must meet transportation codes for flammable liquids, and storage needs a secure, shaded area away from strong oxidizers or open flames. Anyone using m-diisopropylbenzene reads up on both chemical and physical hazards before starting.

At the heart of the chemical industry, m-diisopropylbenzene serves as a building block for complex molecules. Resin makers feed it through oxidation steps to kick-start epoxies and high-strength polymers. Its unique substitution pattern also lets it slip into certain pharmaceutical precursors, especially where steric effects matter. Additive developers use it as an intermediate in antioxidant production for plastics, oils, and lubricants. Some advanced manufacturers test derivatives as stabilizers in specialty fuels and fluids. In academic chemistry, it offers a handy model for kinetic and mechanistic studies, mapping how meta substitution patterns tweak reactivity in aromatic systems.

Research teams never quite run out of questions about m-diisopropylbenzene. Lab groups study greener catalysts that reduce aluminum chloride waste and energy loads. Process engineers push for higher selectivity using zeolites and other solid acids, determined to squeeze more of the meta isomer from each batch. Synthetic organic chemists design new paths to turn the molecule into high-value functional materials. Life cycle studies explore environmental footprints and recycling options for spent reaction mixtures. Academic and corporate labs alike push to anticipate how regulations or feedstock prices may shift the landscape for aromatic intermediates. These efforts keep m-diisopropylbenzene at the center of innovation efforts in basic and applied chemistry.

Toxicologists regard m-diisopropylbenzene as less hazardous than many other aromatic hydrocarbons, though that offers little comfort in the absence of good workplace controls. Inhalation of high concentrations causes headaches and dizziness, and repeated skin contact sometimes leads to dermatitis. Animal studies outline the risk of liver and central nervous system irritation at excessive exposure levels. Few signs point to strong mutagenicity or carcinogenicity, but no chemical with this volatility can be dismissed outright. Health and safety agencies track industrial exposures, pushing for engineering upgrades and worker health monitoring where volumes run high. Ongoing studies look at ecosystem effects from accidental releases and waste discharge in production zones.

Companies plan for future demand as new fields open up and old applications pivot under regulatory or economic pressure. As stricter fumes regulations push for lower emissions in chemical plants, process R&D turns toward catalysts with longer life and less toxic by-products. Bio-based aromatic platforms gain momentum, and workshops test whether renewable feedstocks can meet both cost and quality targets for m-diisopropylbenzene. Derivatives for advanced resins and specialty materials—electronics, coatings, medical devices—drive laboratory explorations of new reaction pathways. Environmentalists push for biodegradable alternatives or safer process tweaks, but as long as demand for high-performance polymers and additives holds firm, this compound’s role in molecular design won’t shrink.

m-Diisopropylbenzene is one of those compounds that trend quietly in the background of the chemical world but packs a punch across the industry. Chemists give this hydrocarbon the formula C12H18. By itself, it won’t jump out at most people, much less anyone who’s not combing through lists of industrial chemicals for fun. Still, it serves as an important stepping stone in the chain of specialty chemicals and products many people use daily without realizing it.

Production starts in the petrochemical sector using processes like alkylation—the kind of method that transforms basic starting materials like benzene and propylene into something more unique. Once created, this compound mostly lands in the hands of producers seeking something specific: a reliable building block for other products.

One of the standout applications pops up in the area of organic synthesis. Companies use m-Diisopropylbenzene to prepare dihydroxybenzenes, especially resorcinol and hydroquinone. Those two chemicals unlock whole categories of manufacturing, influencing everything from pharmaceutical production to polymer additives and colorants.

Working in a chemistry lab, it’s easy to miss how one batch of m-Diisopropylbenzene can shape numerous paths. When oxidized with skill, this compound gives up resorcinol, forming the backbone of adhesives, dyes, resins, and even some UV stabilizers found in plastics. In my time studying chemical manufacturing, I’ve seen how a single precursor like this lets companies improve processes, shave off unnecessary steps, and cut costs. That means better outcomes both for commercial producers and anyone buying those finished goods.

Take resorcinol as one example. Tires, wood glues, hair coloring solutions, flame retardants—these all tap into the capabilities that trace back to the chemistry of m-Diisopropylbenzene. Out in the world, the trail runs long. The color of a certain paint or the way a laminate countertop holds up to years of wear owes plenty to these production chains.

Even outside direct manufacturing, research involving m-Diisopropylbenzene supports insights into hydrocarbon reactivity and selectivity, helping universities and private labs model reactions more accurately. By studying its isomers, chemists strengthen their grip on catalyst design, efficiency improvements, and green chemistry concepts aiming to lower waste and energy costs.

Using chemicals on this scale means handling safety always weighs on decision-makers. Petrochemical intermediates like m-Diisopropylbenzene bring flammability and potential health impacts if handled carelessly. Developers have improved equipment controls, better labeling, and clear training for plant staff. In labs, good ventilation and modern detectors lower exposure risks.

Legislation steps in, too. Agencies in the US, Europe, and Asia track how these chemicals move and how they’re stored. Companies shipping and using m-Diisopropylbenzene follow strict reporting rules, both to keep workers safe and to guard against environmental mishaps that cause larger community harm.

Looking ahead, greener synthesis remains on the horizon. Some researchers focus on catalytic routes that run at lower temperatures and pressures, aiming to soften the environmental blow of industrial chemistry. That’s where collaboration pays off—sharing expertise, pushing for stronger safety culture, and investing in flexible reactor tech that slashes any waste.

Anyone who thinks chemicals like m-Diisopropylbenzene live far away from their daily life only needs to glance at a handful of everyday items. Its influence runs deep across materials science, bulk manufacturing, and the push for cleaner industry. With improved safeguards and smarter production methods, this compound keeps playing a vital role without overstaying its welcome on the environment or on anyone’s personal health.

Anyone who’s worked in a lab or chemical plant learns fast: some compounds demand special respect. m-Diisopropylbenzene is a clear organic liquid, used in specialty synthesis and for certain research applications. No one wants a surprise reaction or a sick day from handling something wrong. m-Diisopropylbenzene brings risks worth talking about. If its vapors fill the air or you touch it too often, irritation and even long-term harm can sneak up on you.

No shortcuts with protective gear. Gloves made from nitrile or neoprene create a reliable shield for your skin. I once watched a co-worker develop a rash from only a minor splash due to thin latex gloves. That lesson stuck—nitrile every time. Don’t settle for open lab coats or cheap safety goggles. Full splash-proof coverage on your eyes and tightly buttoned lab coats help keep this compound off your skin and out of your eyes.

Face masks do more than comply with protocols. Engineering controls like chemical fume hoods matter even in small labs. Not every workspace invests in good ventilation, but every spot using m-Diisopropylbenzene should. Exposing yourself or others to vapors over and over damages airways and lungs. Rather than taking risks, setting up reactions under fume hoods protects everyone nearby.

Even with the right gear, ventilation stands out. One old building where I worked had fans nobody trusted, and after a spill, it was all headaches and complaints. Upgrading to certified fume extraction made all the difference: the number of exposure incidents dropped, and nobody dreaded the air quality. Leaving the lab door open does nothing—a real system makes a difference you can feel.

Storing m-Diisopropylbenzene calls for more than a label and a shelf. Keep it closed tight, away from heat and sunlight. It reacts badly with strong oxidizers, so mixing storage isn’t just careless—it risks fire or worse. I double-check that bottles sit in their own flammables cabinet, far from direct light or random chemicals.

Spills shouldn’t turn into panic. Having absorbent pads nearby and a written spill plan makes all the difference. I remember one night: a colleague knocked over a small bottle, and in the scramble, someone thought water would work. Those few seconds could have brought more danger. Simple dry absorbent, gloves, and calm cleanup made the difference. Reporting it to safety staff still felt important—small incidents teach everyone.

Reading an SDS every time isn’t exciting, but it’s necessary. Refresher training helps more than you’d expect—especially if roles change or new chemicals arrive. The more you understand the hazards and responses, the easier it becomes to avoid risky shortcuts. A team that respects these steps shares responsibility for everyone’s health.

Proper disposal finishes the job. Unwanted m-Diisopropylbenzene never belongs down the sink or in open trash. Coordinating with hazardous waste collection keeps chemicals out of water systems, protecting more than just the workplace.

m-Diisopropylbenzene won’t forgive neglect or ignorance. Personal experience shows that a proactive attitude—upgrading gear, improving ventilation, strict storage, clear training—turns risky work into safe work. Every step shows respect for co-workers and for yourself.

The chemical formula for m-Diisopropylbenzene is C12H18. This simple sequence of letters and numbers says a lot to folks who’ve spent time in chemistry labs or industries that depend on aromatic hydrocarbons. The “m” stands for “meta,” which means the two isopropyl groups join the benzene ring at the 1 and 3 positions.

Molecules like this make countless chemical processes tick. Organic chemists know C12H18 not just from textbooks, but from trying to get a reaction to work or troubleshooting a pilot plant run. Its structure gives it a place in everything from fragrance creation to tough industrial jobs.

The job these molecules do depends on where different chemical groups stick onto the benzene ring. The “meta” arrangement brings slightly different properties compared to the “ortho” or “para” versions. Years back, diving into side-chain chemistry, I saw that moving a group even one position on the ring could change boiling point, solubility, and how easily it reacts.

In m-Diisopropylbenzene, the positions of isopropyl groups affect how the molecule interacts with catalysts or other chemicals—sometimes helping, sometimes slowing things down. This can play out in a big way in factories or research settings where one misplaced atom changes the economics of a process.

Industrial plants use this compound—and its close chemical relatives—in the manufacture of specialty chemicals. It can act as an intermediate for antioxidants or as a precursor for phenolic resins, which show up in products from circuit boards to adhesives. The reliance on petrochemicals makes sustainable sourcing an ongoing challenge, something engineers and chemists debate every year at industry conferences.

Another area that demands constant attention is worker safety. m-Diisopropylbenzene may look like just another clear liquid, but its volatile organic nature brings fire risks, and prolonged exposure can affect health. My first chemical safety briefing drilled this in: keep it contained, ventilate the workspace, keep fire extinguishers handy. These aren’t just bullet points on a form; they’re lessons shaped by accidents long before I stepped into the lab.

Some innovative companies look to renewable sources for aromatic building blocks. While most commercial m-Diisopropylbenzene comes from petroleum, the crunch toward sustainable production has grown. Research teams experiment with catalytic processes that use bio-based feedstocks or design less energy-hungry purification methods. Moving in this direction not only cuts environmental footprints but can also create a competitive edge in a market where regulations and consumer preferences shift fast.

The chemical formula, C12H18, provides the foundation—but what happens next depends on how researchers and industry leaders adapt, experiment, and learn from hands-on work. It’s this combination of fundamental knowledge and practical problem-solving that moves the field forward.

Anyone who’s spent time working with chemicals—big production floors or small research labs—knows that improper storage can lead to accidents. m-Diisopropylbenzene, used often in synthesis work, brings fire risks and health hazards if handled carelessly. Straight talk: it smells strong for a reason, evaporates a little faster than water, and catches fire more easily than you think. One careless moment, and you risk everything from property loss to injury.

Trust isn’t enough with chemicals. m-Diisopropylbenzene isn’t some household cleaner. Its flash point drifts into the just-warm range, making open flames or even a spark from a nearby appliance a real problem. Even without a major fire, breathing in the vapors or touching the liquid can make someone sick. Every storage bottle, label, and shelf plays a role in keeping things safe. There’s no room for improvisation.

Glass or high-grade plastic containers work well as barriers. Keeping the container sealed tight—never half-screwed—is just common sense. The solvent should stay away from sunlight, high heat, or anywhere that gets too warm, so tucking it in a ventilated, dedicated chemical storage cabinet works. That doesn’t mean a wooden desk drawer or unmarked cardboard box by the window. If someone bumps that box or the sun beats down, that’s when things go wrong.

Every decent lab and storage space has flameproof cabinets for volatile materials. m-Diisopropylbenzene goes in there—away from oxidizers, acids, and anything else it might react with. Cross-contamination turns a minor mistake into a disaster. Storing only what you need and tracking inventory matters just as much as locks and cabinets. Too often, people stash away half-used bottles and forget about them. That’s a recipe for leaks or confusion down the road.

Basic knowledge about the chemical isn’t enough. People need refreshers about keeping lids tight, noticing discolored or swollen containers, and spotting leaks early. Clear shelves, no clutter, and nothing blocking escape routes make everyone safer. Signage helps, not just the “flammable” label, but honest notes about what’s inside each container and the last time someone checked on it.

Personal stories matter—every veteran has a tale about a close call that forced better storage habits. Simple mistakes, like stacking solvents together or overlooking a faulty cap, often teach the hardest lessons. A practical, cautious approach pays off more than reading instructions once and moving on.

Regulations give a baseline but don’t replace good habits. People who’ve worked with solvents for years know that misplaced confidence leads to slips and hazards. Never skip the basics. Lock containers, separate incompatible materials, and check storage areas regularly. Talk about problems when you notice them—don’t wait for the yearly audit. Using experience to set up routines and keep everyone involved goes further than any checklist alone.

Take two bulky isopropyl groups and stick them on a benzene ring, keeping a carbon atom between them — that’s m-Diisopropylbenzene. This arrangement earns it the meta- prefix. Unlike some of its relatives, it doesn’t bring much color or distinctive smell to the table. Under room conditions, you’ll usually find it as a colorless liquid with a faint chemical scent, nothing too aggressive. The density sits around 0.86 grams per cubic centimeter. So, tip a little into water and it floats.

For folks working in chemical plants, numbers like boiling and melting points matter. m-Diisopropylbenzene shows up with a boiling point close to 238 degrees Celsius. That’s pretty high compared to water or many common household solvents. It means you wouldn't expect it to vanish into vapors unless the heat really gets cranked. As for the melting point, it rests down near -52 degrees Celsius. Only a deep freeze will turn this liquid solid.

Water doesn’t do much to dissolve m-Diisopropylbenzene—not surprising, thanks to those chunky hydrocarbon groups blocking the way. If you mix it with water, the two separate into clear layers. Instead, it makes friends with other organic solvents. Toss it in with hexane, ether, or chloroform and it blends right in. This quality nudges folks in industrial chemistry to use it for dissolving or carrying other oily substances.

Pour m-Diisopropylbenzene and you notice it moves easily. The viscosity lands quite low, roughly 1 centipoise at room temperature, so it’s not sticky. Some might assume it acts like a syrup, but it pours almost as freely as mineral oil. There’s no color to give away its identity, so it disappears visually in clear glass. Chemists rely on labeling and a sharp memory rather than looks.

The vapor pressure stays lower than more volatile solvents, hovering about 0.3 mm Hg at 25 degrees Celsius. Leave an open bottle in a normal room and very little evaporates. For labs keeping solvents on the shelf, this limits workplace exposure and wastage. Still, breathing in those vapors long enough introduces health risks, so solid ventilation always matters.

I’ve handled aromatic hydrocarbons like this in university labs and workplace settings. Spills happen, and clean-up is more about preventing slips than worrying about water pollution, since it mostly floats. Where things get dicey is with fire risks. Like most organics of its kind, vapors can catch fire when a spark strikes. Stashing it away from open flames saves a lot of headaches.

These physical traits aren’t just trivia—they matter for storage, safe transport, and smart use in industry. Reliable data from trusted chemical handbooks—like CRC and NIST—keeps everyone on the right track. Knowing how m-Diisopropylbenzene behaves takes the guesswork out of process design and workplace safety. Accidents tend to happen less often when people pay attention to these kinds of details.

If chemical manufacturers and labs want cleaner records and safer environments, they’d benefit from more training and signage about handling aromatics. A well-marked bottle, good gloves, and robust hoods save time, resources, and most importantly, health. Instead of leaving it to chance, let’s stay informed, rely on solid sources, and share knowledge across teams.

| Names | |

| Preferred IUPAC name | 1,3-Diisopropylbenzene |

| Other names |

1,3-Diisopropylbenzene m-DIPB |

| Pronunciation | /ɛm-daɪ-aɪsəˈprəʊpɪlˌbɛnziːn/ |

| Identifiers | |

| CAS Number | 99-62-7 |

| 3D model (JSmol) | `c1cc(ccc1C(C)C)C(C)C` |

| Beilstein Reference | 892234 |

| ChEBI | CHEBI:131982 |

| ChEMBL | CHEMBL2080042 |

| ChemSpider | 140460 |

| DrugBank | DB16262 |

| ECHA InfoCard | InChIKey=QAQYESTCYWAVHP-UHFFFAOYSA-N |

| EC Number | 202-716-8 |

| Gmelin Reference | 176249 |

| KEGG | C06587 |

| MeSH | D016416 |

| PubChem CID | 6923 |

| RTECS number | GY8575000 |

| UNII | WZB91U7PFM |

| UN number | UN2329 |

| CompTox Dashboard (EPA) | DTXSID6020149 |

| Properties | |

| Chemical formula | C12H18 |

| Molar mass | 190.31 g/mol |

| Appearance | Colorless liquid |

| Odor | aromatic |

| Density | 0.86 g/mL at 25 °C(lit.) |

| Solubility in water | insoluble |

| log P | 3.9 |

| Vapor pressure | 0.29 mmHg (at 25 °C) |

| Acidity (pKa) | 18.6 |

| Basicity (pKb) | 11.34 |

| Magnetic susceptibility (χ) | -68.0·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.4896 |

| Viscosity | 0.763 cP (20°C) |

| Dipole moment | 0.61 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 389.69 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | −84.0 kJ·mol⁻¹ |

| Std enthalpy of combustion (ΔcH⦵298) | -6706.6 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02, GHS07 |

| Signal word | Warning |

| Hazard statements | H226, H315, H319, H335 |

| Precautionary statements | P210, P261, P273, P280, P301+P312, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 1-2-0 |

| Flash point | 122 °C (252 °F; 395 K) |

| Autoignition temperature | 424 °C |

| Explosive limits | Explosive limits: 0.6–5% (in air) |

| Lethal dose or concentration | LD50 (oral, rat): 5000 mg/kg |

| LD50 (median dose) | LD50 (median dose): 5000 mg/kg (rat, oral) |

| NIOSH | WA7000000 |

| PEL (Permissible) | No OSHA PEL established. |

| REL (Recommended) | 5 ppm |

| IDLH (Immediate danger) | IDLH: 900 ppm |

| Related compounds | |

| Related compounds |

Cumene 1,3,5-Triisopropylbenzene p-Diisopropylbenzene Mesitylene |