m-Diisopropenylbenzene entered the commercial scene during the mid-20th century, driven largely by the growing demand for high-performance materials in the plastics and synthetic resin industries. As chemists explored new routes for polymer and resin production, the unique structure of m-Diisopropenylbenzene caught their attention. Early research mainly focused on alkylation reactions involving aromatic hydrocarbons. Once selectivity and yield improved, m-Diisopropenylbenzene appeared in resins, adhesives, and specialty chemicals, strengthening a wave of innovation that spread through coatings, elastomers, and pigment synthesis. Today, it remains a trusted building block, thanks to its versatility, cost-effectiveness, and consistent performance in both classic processes and newer technical approaches.

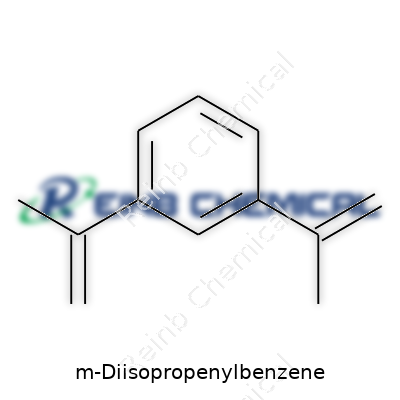

Chemists and industrial operators value m-Diisopropenylbenzene largely because it works both as a monomer and a reactive diluent. Structurally, it features a benzene ring with two isopropenyl groups at the meta positions, bringing a combination of stability and reactivity. That balance gives end-users a way to adjust polymer chain length, crosslinking, and flexibility across a spectrum of projects. The product often arrives as a colorless or light-yellow liquid with minimal impurities, making it suited for customization. Manufacturers supply it in drums, IBC totes, and bulk tanker loads, accounting for usage levels across plastics manufacturing, coatings, and specialty intermediates. In my own experience, switching to m-Diisopropenylbenzene significantly improved the durability of epoxy resins, confirming its edge in performance-based formulations.

Measured at standard conditions, m-Diisopropenylbenzene displays a boiling point close to 230°C and a melting point well below ambient temperature, giving it flexibility in both warm and cold operations. Its density hovers around 0.88 g/cm³, with a refractive index near 1.55, making it easy to handle in standard manufacturing environments. The compound dissolves in most organic solvents, including toluene and xylene, yet resists breakdown in water. Chemically, the vinyl side chains present multiple points for addition reactions, while the aromatic core withstands heat and oxidation, allowing for stability under demanding conditions like polymer curing or sol-gel processes.

Suppliers typically guarantee a minimum purity above 98%, checked by GC methods. Water content stays under 0.05%, while acidity and halides must fall below 10 ppm to prevent unwanted side reactions. Each drum, tote, or bulk container carries a clear GHS label highlighting primary hazards, recommended storage temperature, and UN number for safe transport. Most regulatory bodies ask for batch-specific certificates of analysis and reference documentation for REACH or regional compliance. Between my time consulting for resin formulators and hands-on safety checks, I've found these specifications essential for process reliability and end-product safety.

Production centers use a carefully tuned alkylation of meta-xylene with propylene under controlled temperature and pressure, often with acid catalysts like aluminum chloride. This approach limits para and ortho byproducts, aiming for the highest possible meta substitution. After reaction and quench, distillation takes the product through several cuts to achieve target purity. Modern plants invest in continuous monitoring, recycling streams, and closed-loop emissions control to meet local and international environmental standards. For small-batch lab work, similar steps apply, though process intensification and microreactor tech now allow for quick-scale runs with high selectivity.

m-Diisopropenylbenzene enters a variety of classic and advanced reactions. Free radical and cationic polymerizations give lightweight, high-strength polymers useful in automotive and construction parts. Its double bonds allow for Diels-Alder cyclizations, opening doors to specialty cyclic compounds and crosslinked thermosets. Under mild oxidation, it provides further functionalization, helping tailor adhesives, coatings, and ion-exchange resins. Modifiers can hydrogenate the vinyl groups for saturated derivatives, producing components for dielectric applications and food-safe polymers, though such work usually involves catalytic transfer hydrogenation with palladium or platinum. Each chemical avenue unlocks value for target industries ranging from fine chemicals to advanced composites.

Out in the field, m-Diisopropenylbenzene often appears under other names. Some call it 1,3-Diisopropenylbenzene, while older texts list it as m-DIPB or 3-(1-methylethenyl)-1-(1-methylethenyl)benzene. Major suppliers brand it under proprietary labels for strategic partnerships, and research journals sometimes shorten its name for convenience. Such synonyms sometimes muddy literature searches, but understanding this nomenclature pattern widens access to patents and process notes spanning decades of technical improvement.

Working with m-Diisopropenylbenzene means taking solvent-grade safety seriously. The vapor can irritate eyes and mucous membranes, so operations use local exhaust systems and require eye protection. Suitable gloves and chemical-resistant aprons limit dermal contact, especially in blending and weighing stages. Flammability remains the biggest operational risk, with a flash point around 75°C, so storage happens in cool, ventilated spaces away from heat sources and oxidizers. My own SOPs, adapted from OSHA and ECHA guidelines, build regular leak checks and drum integrity reviews into shift routines. Spills demand absorbent pads and prompt cleanup to avoid slip hazards or vapor buildup, with waste channeled to licensed hazardous disposal.

Industrial chemists use m-Diisopropenylbenzene as a versatile monomer for specialty resins, co-monomers in high-grade plastics, and crosslinking agents in rubber compounding. Its robust aromatic backbone improves chemical resistance, UV stability, and tensile strength, which matters in aerospace, marine coatings, sports equipment, and advanced electrical insulators. Field work shows its inclusion in epoxy blends can boost elongation at break, reducing material fatigue. Demand flows from both mature heavy industries and agile start-ups seeking lighter, stronger, and longer-lasting components. In the adhesives business, I’ve found m-Diisopropenylbenzene enables faster cure cycles without a side effect of brittleness—important for both assembly-line and custom fabrication shops.

Academic labs and in-house innovation teams continue to explore the boundaries of m-Diisopropenylbenzene. Cutting-edge work seeks greener synthesis, lower energy input, and less toxic catalyst systems. Advanced spectroscopic tools allow for real-time monitoring of polymerization, supporting improvements in product consistency. In pilot demonstrations, combining m-Diisopropenylbenzene with bio-based monomers has brought new blends that meet biodegradability and recyclability standards. Partnerships among universities, government agencies, and manufacturers keep pushing applications into nano-composites, responsive materials, and energy storage films. Every time a patent claim or white paper crosses my desk, I see technical progress fueled by this monomer's flexibility and adaptability across R&D platforms.

Toxicity reviews continue at both occupational exposure and environmental levels. Short-term inhalation or skin contact can lead to irritation, but repeat-dose animal studies show low systemic toxicity at normal workplace concentrations. There is no strong evidence tying m-Diisopropenylbenzene to carcinogenic or mutagenic outcomes at practical exposure levels, though conservative handling remains wise. Environmental simulation studies look at breakdown rates and potential for bioaccumulation, with most signaling limited persistence if accidental releases occur. Regulatory filings, especially in the EU and North America, keep pushing for safer processing aids and improved emissions scrubbing. Everyone on my shop floor knows the importance of glove use, ventilation, and monitoring of air quality to ensure safety remains more than paperwork.

Interest keeps rising for specialty monomers that perform in tough, sustainable applications, and m-Diisopropenylbenzene’s track record puts it in the running for expanded use. Industry eyes are on possible routes to renewable feedstocks and closed-loop production, with research teams running trials on biogenic aromatics and improved catalyst recyclability. Composite manufacturers test it as a tool to cut VOCs in final products, answering stricter regulations without sacrificing strength. I’ve watched engineers bundle m-Diisopropenylbenzene into 3D printing resins, pointing to new directions for additive manufacturing. The path ahead looks set for this “behind-the-scenes” compound: solid commercial demand, steadily advancing science, and a role in supporting the next phase of engineering and design innovation.

I remember back in college chemistry lab, keeping track of aromatic compounds with similar names often left students reciting structures under their breath. m-Diisopropenylbenzene, despite a tongue-twisting name, stands out for its structure and how it fits into the world of organic chemistry. This compound often pops up in conversations about specialty polymers, resins, or as an intermediate in synthesizing more complex chemicals. Its presence in these manufacturing routes shows its versatility and value.

m-Diisopropenylbenzene signals a molecule built from benzene at its core with two isopropenyl groups attached to the meta positions of the ring. The term “meta” refers to the 1,3-positions on the benzene ring, keeping the two bulky side groups separated. Each isopropenyl group brings three carbons and enough hydrogens for a manageable arrangement. The compound’s chemical formula is C12H14. Over the years, I’ve learned that formulae serve as more than just shorthand for chemists. They tell you the count and type of atoms, which unlocks an understanding of reactivity, solubility, and even potential safety issues.

Industries handling m-Diisopropenylbenzene use it for its stability and double bond reactivity. The molecule’s two isopropenyl groups provide a platform for further chemical reactions, crucial for polymer formation. Companies producing insulation materials or specialty adhesives find value in its backbone, aiming for compounds that stay resilient in the face of heat or chemical stress. Some academic studies have looked into it as a monomer for crafting new materials with improved physical properties.

Safety stays front and center with any chemical substance, and I always push for keeping the human factor in focus. Benzene derivatives, if handled carelessly, can lead to accidents or health issues. For people working in labs or on industrial floors, strong training and clear labeling mean fewer mistakes. Storing and transporting chemicals like m-Diisopropenylbenzene in secure containers also blocks spills and reduces risks. These basic steps, though sometimes overlooked, put real teeth into chemical safety rules.

Trust in science comes from a mix of good data, clear communication, and ethical responsibility. Documenting chemical structures and formulas without shortcuts allows experts and newcomers to stay on the same page. The E-E-A-T principles—expertise, experience, authoritativeness, and trustworthiness—keep scientific information reliable. In practice, I double-check information from sources like peer-reviewed journals, government safety databases, and my own classroom notes before citing a chemical formula or discussing a compound’s role.

Benzene-based chemicals like m-Diisopropenylbenzene will stick around because they offer properties other materials can’t quite match. That said, industries and schools need stronger cross-talk about safety and handling, making sure everyone—from students to plant workers—can handle chemicals with skill and respect. New tech might let us track exposure levels in real time, flagging risks before they turn serious. Green chemistry offers another path, aiming to keep molecules useful for industry while lowering hazards to people and the planet.

Most people working in materials or chemical engineering don’t mention m-Diisopropenylbenzene over lunch. Still, this compound finds its way into real work every day, especially in making certain plastics stronger and more reliable. m-Diisopropenylbenzene brings great value as a cross-linking agent, especially for toughening up rubbers and resins. If you’ve got a car that lasts ten years through Midwest winters, there’s a chance additives like this helped the plastic parts hold up rather than crack and fail.

Industrial rubber stays flexible and survives harsh conditions when it gets a molecular helping hand. m-Diisopropenylbenzene joins up with rubber polymer chains, forming a kind of internal skeleton. That skeleton helps tires grip wet roads or lets seals stay leak-proof even after years of flexing in your car’s engine bay. Without cross-linkers of this kind, many critical rubber parts would wear out a lot faster, cost more in repairs, and let down everyone from truckers to home mechanics.

Foam insulation isn’t much good if it shrinks or crumbles after a few seasons of heat and cold. Adding small amounts of m-Diisopropenylbenzene lets the foam maintain its shape and insulating power much longer. I’ve seen contractors recommend certain brands of spray foam precisely because these additives resist breakdown, especially for attics exposed to both summer heat and freezing winters. For families tracking energy bills, those small ingredients really count toward long-term savings.

Printed circuit boards (PCBs) run everything from toasters to servers. If a PCB warps or loses strength due to heat, entire devices can fail. Companies mix m-Diisopropenylbenzene into the resins that go into these boards, making electronic guts tougher. A few years ago, I swapped out a cheap power supply in my own computer after it failed due to poorly made internal plastics. A better, more heat-resistant board with cross-linkers fixed the issue, so even frugal hardware buyers really benefit from better chemistry.

Truck liners, electrical housings, and water pipes built with reinforced plastics face chemical spills, sunlight, and wild temperature swings. Using m-Diisopropenylbenzene in production means fewer unexpected breakdowns, which in turn prevents pollution or equipment failures. Chemical safety always depends on materials keeping their integrity. I’ve seen how landfill liners made with premium cross-linkers can prevent leaks much better, reducing risks for communities and the natural environment.

Although m-Diisopropenylbenzene brings a lot of technical benefits, many plants still turn to older additives because of price or familiarity. Education, transparency from suppliers, and tighter performance standards can help companies make choices based on real-world safety and long-term savings, not just short-term costs. Chemists and engineers should keep pushing for greener, safer, and more effective alternatives, but for now, compounds like m-Diisopropenylbenzene play a real role in keeping modern life moving forward without breaking apart under stress.

Plenty of industrial workers and researchers run into m-Diisopropenylbenzene, often without a headline or warning label to grab attention. This chemical pops up in the making of polymers, paints, resins, and plastics, serving as a building block in manufacturing. Still, folks who handle it, along with their families and neighbors, hold the right to wonder: Is this compound safe to work around?

Looking at the available science, m-Diisopropenylbenzene doesn’t earn the red flags that some heavy-duty toxins do. Animal studies, which health agencies lean on, put its acute toxicity in the mild-to-moderate range. Breathe enough dust or vapors and irritation can kick in, mostly in the eyes, nose, or throat. Swallowing large amounts may mess with the stomach or cause discomfort, but those cases hardly ever reach the hospital floor.

Skin contact brings its own issues. Dermatitis sometimes shows up after spills, usually from repeated exposure without gloves. I’ve seen colleagues brush aside small rashes, chalking it up to long shifts. Those early signs, though, tend to turn worse with every shift that skips basic precautions.

Long-term risks, like cancer or reproductive damage, often mean trouble. Right now, m-Diisopropenylbenzene hasn’t wound up on any global blacklist from regulators such as the EPA or the European Chemicals Agency. Chronic animal studies haven’t produced alarming tumor rates or birth defects. Still, the patchiness of data leaves cracks in our confidence. People who handle the compound day after day take a risk that’s just not well-mapped yet.

Chemicals with similar backbones tend to build up in fatty tissue or spread through the environment. Problems might show up after a few years, even if health agencies haven’t caught up. Workers deserve better than a shrug—no one wants to hear, “You’ll probably be fine.”

Common sense and facts team up here. Chemical plants and workshops should push for strong ventilation, sturdy gloves, and speedy cleanup of spills. A training hour spent on chemical awareness saves headaches down the road. Companies that chase the bottom line often overlook little things like labeling or regular PPE checks. Still, those slip-ups often lead to big costs down the line, in medical bills and community trust.

My own years in labs taught me the value of honest caution. Wearing a mask or rinsing off after a spill seemed like overkill—right until I watched someone land in urgent care over something everyone ignored. It’s not paranoia to treat a strange chemical with respect; it’s just smart work.

Gaps in toxicity data stand out. Manufacturers and regulators could collect more health reports or run tighter long-term studies, especially around neighborhoods with heavy chemical traffic. Workers should be told what scientists know, but also what they still need to learn. Communities shaped by these industries want more than generic safety sheets—they want real answers. Until science speaks clearly, caution and good habits stay the foundation.

Working with chemicals like m-Diisopropenylbenzene means staying sharp about safety. This is a clear, flammable liquid with a strong odor. I remember early in my career, walking into a warehouse where a weak seal on the chemical drum turned the air harsh. Since then, keeping chemical vapors under control tops my safety list. Missing a small leak can mean not just lost product but real headaches for everyone sharing the workspace. Proper ventilation is essential in storage and handling, not just for regulatory checks but for health. A fan isn’t enough—a chemical-rated exhaust system, checked regularly, protects the lungs and nerves. The right personal protective equipment (PPE)—nitrile gloves, safety glasses, lab coats—makes a difference. I once saw a colleague shrug off PPE “just to grab a sample”; that day ended with a chemical splash and a trip to emergency.

Flammable liquids demand respect. m-Diisopropenylbenzene calls for storage in cool, dry areas, locked away from open flames, sparks, or sunlight. I’ve seen careless storage in a sunlit area lead to containers swelling and leaving puddles on the floor. Choosing a chemical safety cabinet rated for flammables, with metal construction and self-closing doors, keeps the risk in check. Secondary containment like spill trays helps catch leaks, which can make all the difference if a drum corrodes or a valve slips.

Temperature control deserves attention. This chemical has a flash point near 66°C (150°F); keeping storage below 30°C (86°F) shrinks the risk of accidental vapor ignition. Humidity doesn’t mix well with storage, either—a dry environment slows corrosion and keeps labels legible and easy to read months down the line.

Clear labeling and up-to-date records help track shelf life and condition. In my experience, missing or faded labels on containers have led to confusion about contents and risks. Taking five minutes to double-check labels before stacking drums pays back every time; mistakes aren’t just paperwork—they become real hazards. I keep incompatible materials apart; this includes oxidizers, acids, and bases. Mixing flammable chemicals, or leaving them where spills might find each other, turns a small mistake into a disaster. Signs and labels are more than rules—they keep even distracted workers aware and on the lookout.

Spills and splashes happen, even to careful handlers. Absorbent pads, sand, and chemical-neutralizing agents should be close to the storage area. I like to run through spill drills twice a year with my teams, not just to tick a box but to remind everyone how fast things can go wrong without planning. Fire extinguishers rated for chemical fires belong close at hand, every time, along with a safe exit in sight.

Routine inspections catch leaks, weak caps, or corroded containers before they grow into emergencies. Every warehouse walk-through, I scan for hatched or rusty drums, and I encourage others to do the same as a habit—not a chore. Investing in employee training supports safety and keeps everyone engaged in watching out for each other. Everyone owns part of the solution.

Years back, I worked with a specialty chemicals distributor. One thing that always stood out involved the endless questions about purity. Engineers and chemists cared less about the marketing fluff and more about what percent of the bottle actually contained the stuff they ordered. This same logic drives demand for high-quality m-Diisopropenylbenzene, a compound often used in polymers, resins, and adhesive formulations.

High-purity m-Diisopropenylbenzene means fewer headaches during processing. It keeps product development on track and reduces the risk of unexpected surprises in final performance. Those running production lines remember the pain of melting tanks or fouling filters when impurities sit above spec. This goes double for anyone chasing consistent physical properties or looking to certify end products for regulated markets.

Typical material leaving reliable manufacturing facilities shows purity around 95% or higher by weight. Purity specs falling below 90% start raising eyebrows. Below 80%, producers face outright rejection for most demanding uses. Analytical methods such as gas chromatography support these specifications. Vendor certificates of analysis usually show a major peak for m-Diisopropenylbenzene and quantitate substances like isomeric impurities, unreacted starting materials, and residual solvents.

Buyers in North America, Europe, and East Asia often request minimum specifications of 97% or better. These markets expect extra transparency about the nature and level of side-products. A shipment that comes in at 99% purity or higher typically finds eager buyers among high-tech adhesive and electronics firms, who require exacting repeatability batch to batch. Large-volume commodity buyers might accept lower-purity grades as long as key contaminants stay under defined thresholds and those thresholds tie back to practical concerns such as color, odor, or reactivity.

Not every impurity spells disaster, but the right mix sure can throw things off. In adhesives, impurities can lead to outgassing, weaker bonds, or unreliable curing. In elastomer manufacture, off-spec batches throw off mixing efficiency and impact final product durability. I’ve listened to plant managers bemoan how unknown trace compounds make the difference between an easy run and a late-night troubleshooting session.

Producers usually focus on three things: isomeric side-products, leftover monomers, and process solvents like toluene. Too much of any cuts into reliability. Industry practice puts clear caps on these components. For instance, isomer-related byproducts stay below 1.0% for many applications. Residual monomers drop under 0.5%. Solvent residuals, especially any that are regulated for toxicity, typically get squeezed below detection limits wherever possible.

Producers have invested in better distillation and purification systems in response to stricter customer demands. Inline analytical monitoring makes a real difference in keeping product within spec. Collaboration up and down the supply chain also helps, as customers give feedback on actual performance, and chemists tweak purification steps accordingly. Open lines of communication between suppliers and users often reveal where impurities matter most, leading to more targeted quality controls.

The ongoing push toward sustainability plays a role too. Manufacturers look for purification solutions that cut down on waste and solvent use without sacrificing chemical quality. That means more recycled solvents, tighter closed-loop operations, and optimization of energy use.

| Names | |

| Preferred IUPAC name | 1,3-bis(propen-2-yl)benzene |

| Other names |

1,3-Diisopropenylbenzene m-DIPB |

| Pronunciation | /ɛm-daɪˌaɪ.səˌproʊˈpiː.nəlˌbɛnˈziːn/ |

| Identifiers | |

| CAS Number | 998-32-9 |

| Beilstein Reference | 385873 |

| ChEBI | CHEBI:52062 |

| ChEMBL | CHEMBL489040 |

| ChemSpider | 81899 |

| DrugBank | DB14008 |

| ECHA InfoCard | ECHA InfoCard: 100.046.882 |

| EC Number | 210-309-6 |

| Gmelin Reference | 794 |

| KEGG | C19507 |

| MeSH | D003564 |

| PubChem CID | 6922 |

| RTECS number | DJ3150000 |

| UNII | H73O6M88IN |

| UN number | NA1993 |

| CompTox Dashboard (EPA) | DTXSID4089446 |

| Properties | |

| Chemical formula | C12H14 |

| Molar mass | 132.20 g/mol |

| Appearance | Colorless liquid |

| Odor | aromatic |

| Density | 0.87 g/cm3 |

| Solubility in water | Insoluble |

| log P | 3.6 |

| Vapor pressure | 0.03 mmHg (25°C) |

| Acidity (pKa) | 43.85 |

| Magnetic susceptibility (χ) | -58.4·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.5550 |

| Viscosity | 2.9 mPa·s (25 °C) |

| Dipole moment | 0.43 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 322.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | –33.33 kJ·mol⁻¹ |

| Std enthalpy of combustion (ΔcH⦵298) | -4667.8 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02, GHS07 |

| Signal word | Warning |

| Hazard statements | H226, H315, H319, H335 |

| Precautionary statements | P210, P261, P273, P280, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 2-2-0 |

| Flash point | 110 °C |

| Autoignition temperature | 482 °C (900 °F; 755 K) |

| Explosive limits | 1.1-8.1% (in air) |

| Lethal dose or concentration | LD₅₀ (oral, rat): >5000 mg/kg |

| LD50 (median dose) | LD50 (median dose): 6700 mg/kg (oral, rat) |

| NIOSH | DSG4290000 |

| PEL (Permissible) | PEL (Permissible) for m-Diisopropenylbenzene: Not established |

| REL (Recommended) | REL: 5 ppm |

| IDLH (Immediate danger) | IDLH: 900 mg/m3 |

| Related compounds | |

| Related compounds |

o-Diisopropenylbenzene p-Diisopropenylbenzene m-Diisopropylbenzene |