Diisopropylbenzene does not pop up in daily conversation, but its journey intertwines tightly with the evolution of the chemical industry. Early in the twentieth century, as global demand for new materials ballooned, chemists started recognizing the potential sitting within substituted benzenes. Efforts by chemists like Friedel and Crafts in the late 1800s spurred exploration into alkylation reactions, laying the groundwork. By the 1930s, with the petrochemical boom and industrial focus sharpening on synthetic pathways, diisopropylbenzene started to find a real home in production facilities. Research groups across Europe and North America synthesized various isomers and mapped out properties that would later support a broad collection of downstream applications. My university’s library—buried in old journals—still holds gritty hand-typed papers where early researchers struggled with purification methods. They probably never predicted the range of uses that would spring out of a fairly simple molecule.

In practice, diisopropylbenzene stands as a versatile compound in organic synthesis and industry. Commercial suppliers ship it in drums or bulk tanks, often targeting companies making phenolic resins or seeking specialty solvents. Chemists appreciate this molecule both as a solvent and as an intermediate. It is not a household name, but it plays a behind-the-scenes role in making antioxidants, fragrances, and polymer building blocks. Chemical plants keep this material handy because of its reactivity, especially for subsequent transformations leading to hydroperoxide formation and phenolic intermediates.

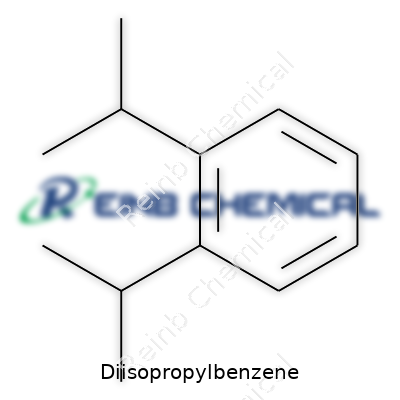

Diisopropylbenzene appears clear and colorless, resembling many aromatic hydrocarbons. Its molecular formula, C12H18, sets it apart from smaller aromatics with added branching that influences its boiling point and stability. At standard pressure, it boils just above 200°C, and its liquid density hovers around 0.86 g/cm³, making it lighter than water but heavier than most simple alkanes. Volatility fits nicely for many separation processes. The isomers—1,2-, 1,3-, and 1,4-diisopropylbenzene—show subtle but meaningful differences in reactivity and handling, though commercial focus mostly centers on the 1,3- and 1,4-variants. Unlike toluene or xylene, its extra alkyl groups provide both steric hindrance and electron-donating qualities, tuning its chemistry for specific downstream reactions.

Industrial packages of diisopropylbenzene bear labels reflecting purity, water content, and isomeric composition. Routine shipments specify purity levels greater than 98%, with moisture usually below 0.1%. Chemical safety numbers and transport classifications align with standards set out by agencies like OSHA, the European Chemicals Agency, and the UN for flammable liquids. Labels usually don’t leave room for mystery. They name the producer, batch, production date, and regulatory codes. Detailed data sheets cover melting and boiling ranges, permissible impurities, and permitted stabilizing additives—if any. With strict regulatory scrutiny, each consignment carries a Material Safety Data Sheet (MSDS) providing customers, handlers, and freight professionals immediate access to hazard codes, personal protective equipment (PPE) requirements, and first aid steps.

Today’s chemical plants synthesize diisopropylbenzene in one main step using Friedel-Crafts alkylation. Benzene reacts with propylene (or isopropyl chloride in older tech) in the presence of a Lewis acid like aluminum chloride or zeolite-based catalysts. The trick lies in managing the thermodynamics and kinetics to favor diisopropyl over mono- and triisopropyl derivatives. Plants use temperature, reactant ratios, and selective distillation to zero in on the desired product. Raw output runs through column after column, squeezing out by-products and boosting purity until manufacturers meet industry specs. It’s impressive how optimization—guided by decades of pilot plant data—lets operators tune the process for maximum yield with minimum waste. Homemade benchtop attempts rarely compare to the efficiency or selectivity seen in full-scale operations.

Chemists treasure diisopropylbenzene’s hydrogen atoms sitting on the aromatic ring. Oxidizing agents such as air (in the presence of catalysts) convert this hydrocarbon into diisopropylbenzene hydroperoxide, an intermediate that unlocks access to valuable phenols. Sometimes, sulfonation, nitration, or halogenation of diisopropylbenzene paves the way for further functionalization. Its isopropyl groups steer incoming chemical species during electrophilic aromatic substitution, guiding where reactions take place. In large reactors, these characteristics allow companies to produce antioxidants, epoxy hardeners, and even certain plasticizers with a level of precision smaller aromatic molecules do not easily afford.

Diisopropylbenzene goes by several names in catalogs worldwide. I’ve seen it listed as DIB, 1,3-Diisopropylbenzene, 1,4-Diisopropylbenzene, and p-Diisopropylbenzene—each reflecting the arrangement of isopropyl groups on the benzene ring. Some manufacturers assign product codes, especially for blends, while trade names rarely stick in technical settings. Bulk buyers and lab scientists alike recognize the core chemical names more than any branding attempt. A quick scan through a regulatory or chemical inventory database unearths its CAS number, making tracking and compliance checks straightforward.

Few outside the lab realize how many invisible safety rules surround handling diisopropylbenzene. The compound catches fire easily, just like many aromatics. Spill one beaker across a workbench, and the sharp, hydrocarbon odor demands a rapid response. On a plant scale, this calls for flameproof pumps, tight seals, and well-drained spill containment. Safety Data Sheets urge the use of gloves, splash goggles, and, in enclosed spaces, respirators. Chronic exposure can cause skin or respiratory irritation, so companies enforce training, storage in cool areas, and routine leak checks. Fire departments in chemical zones drill specifically for aromatic hydrocarbon fires, and municipal codes require plans for safe venting and waste handling. Everyone, from new hires to senior engineers, gets a strong sense of responsibility for safe chemical stewardship.

For a molecule without household fame, diisopropylbenzene gets shipped to a long list of industries. The biggest draw comes from the intermediate stage in making phenols and hydroquinone derivatives. Specialty chemicals companies blend it into antioxidant formulations to slow plastic and rubber degradation. Fragrance makers use it for specific musk and aromatic notes that perfumes require. The plastics sector taps its derivatives as stabilizers or polymerization aids. Older literature records some use in medical and agricultural chemicals—fields hungry for new functional molecules. Its hydrophobic nature helps as a solvent in certain niche industrial processes and formulations. Over the years, diisopropylbenzene-based chemistry quietly enabled a range of materials we all use every day, whether we realize it or not.

Fresh research targets both process intensification and environmental impact. Labs now chase catalysts that boost yield and cut unwanted by-products. Some teams push for greener synthesis routes, such as solid acid catalysts replacing corrosive aluminum chloride. Instrumental analysis methods—gas chromatography, NMR, FTIR—map out subtle process fluctuations in real time, letting chemists respond with surgical precision. Research into recycling schemes and solvent recovery lowers waste, pressure, and cost. Graduate students, many just starting their chemistry journey, test new reactor designs and simulate large-scale batch runs to uncover new operational sweet spots. These improvements may sound abstract, but they add up to safer factories, cheaper products, and less pollution.

Most technical reviews flag low acute toxicity but point out extended exposure risks. Rodent studies show some organ impact at high doses, which prompted limits on airborne levels in workplaces. Droplets on skin can cause irritation; inhaling vapors above recommended limits may trigger headaches or dizziness. Ongoing work looks at metabolic breakdown and possible long-term effects, especially as micro exposures add up for process operators. Environmental toxicology teams investigate breakdown rates in soil and water, searching for persistent residues. Government regulators use these findings to set exposure limits and mandate disposal methods. My own first encounter with the safety literature gave me a firm respect for the difference between laboratory curiosity and industrial responsibility.

Looking ahead, diisopropylbenzene has staying power. Demand for advanced antioxidants, cleaner polymer additives, and custom phenolic chemicals keeps growing with each new industrial need. Researchers chase higher atom economy and greener alternatives without ditching the molecular backbone that works so well. Regulatory tightening continues—especially for emissions, waste, and trace residues. Companies build flexibility and transparency into supply chains, using barcoded drums and live tracking for shipments. Start-ups and established manufacturers see value in plug-and-play modular systems for small-batch specialty work, giving them a leg up as customer needs shift. Environmental concerns mean process engineers tune reactors to minimize leaks, upcycle waste, and nail down closed-loop methods. As industries push the envelope on both performance and sustainability, diisopropylbenzene’s story remains an ongoing experiment, blending chemistry, innovation, and responsibility every step of the way.

Factories and research labs depend on a range of chemicals to create everyday products. One less-known but important player in this process is Diisopropylbenzene. With a structure built from benzene and two isopropyl groups, this compound shows up in surprising places, especially where specialty chemicals come into play.

I first heard about Diisopropylbenzene back in college, during a tour of an industrial chemistry plant. Chemists there pointed out how valuable it is for making hydroperoxides. These aren’t just chemicals with a long name — they serve as critical intermediates for producing phenol and acetone. Just look at the demand for phenol: companies worldwide count on it to produce adhesives, laminates, medicines, and plastics. Without intermediates like Diisopropylbenzene, shelves would look a lot different.

So what does this mean for the rest of us? Take polycarbonate plastics as an example — bottles, electronics, even eyewear depend on reliable sources of phenol. Hospitals and clinics trust medical devices made from these plastics to remain durable and safe for patients. Each step in the supply chain matters.

Acetone, which starts with the same building blocks, cleans lab equipment and helps apply coatings in everything from home improvement projects to automotive work. Few think of Diisopropylbenzene when painting a room or buying a plastic jug, but without upstream chemicals like this, modern life stutters to a stop.

Working with powerful chemicals requires sharp oversight. Diisopropylbenzene comes with health risks. Direct exposure can harm the skin, eyes, and lungs. Different studies show that it doesn’t break down quickly in the environment, making safe handling and disposal an essential part of any operation.

Lab staff know how to keep themselves safe — gloves, goggles, strict handling protocols. But not every worksite puts worker health first, which leads to headlines when spills or accidents occur. Community health researchers notice an uptick in concerns near chemical plants that handle these compounds. Avoiding negative outcomes starts with more transparency about handling, investing in staff training, and regular inspections by regulatory agencies.

Factories need to keep working, but protecting communities shouldn’t take a back seat. Tougher permitting processes make sense, giving the public a stronger voice in decisions. Emergency response plans deserve investment and clear communication. Companies that step up on safety and testing see problems before they spill over.

Researchers continue searching for greener alternatives. Biodegradable chemicals or innovations that require fewer hazardous intermediates open the door to safer workplaces and less-polluted air. These solutions take time and investment, but the long-term payoff arrives as cleaner water and fewer health emergencies.

Knowing where our products come from helps everyone push for better standards. If Diisopropylbenzene stays part of the supply chain, accountability remains essential so industry growth never comes at the expense of health or safety.

Diisopropylbenzene finds its way into all kinds of chemical processes. Walk into any organic chemistry lab or specialty plant, and you'll probably see it on the shelf. The stuff doesn’t grab headlines, but it's no toy. Its vapors pack a wallop, and a careless approach leads to costly mistakes. Mishandling can leave you with skin burns, sore throats, or even something worse.

No one in the lab reaches for diisopropylbenzene barehanded. Nitrile gloves handle the liquid without breaking down. Cheap latex won't cut it; over time, the chemical sneaks through. Goggles shield eyes from splashes—I'm talking the snug kind, not those flimsy visitors’ glasses. Lab coats stay buttoned and sleeves cover wrists. Open shoes? Big mistake. I learned early; closed toes and long pants keep your skin safe from spills that are hard to see until they burn.

Getting sloppy with ventilation is an invitation to trouble. Diisopropylbenzene lets off fumes that hit the respiratory tract fast. In a closed-up room, even a small spill can make breathing rough. Fume hoods take the risk out of pouring and measuring—nobody wants to be the guy wheezing or seeing double because of short-term exposure.

Sparks near this chemical can end a good day real quick. Its flash point means static electricity can set off a fire, especially in dry weather. I learned to keep containers grounded and to avoid mixing electronics and open bottles. No hot plates, no open flames, no quick fixes. Spills get cleaned right away, and rags soaked with chemical head straight into the right disposal bin, not a regular trash can where they start heating up.

Stashing diisopropylbenzene in metal drums without tight seals means evaporation loss and extra risk. The containers need to close tight. No sun or heat source shines on them, and inventory logs should match what you have on the shelf. Once, a missing bottle led to a half-day search—a risk nobody in real labs finds acceptable.

Training pays off. Every job with diisopropylbenzene starts with knowing the safety data sheet (SDS) by heart. No one assumes the person next to them “just knows” what to do in an emergency. Fire extinguishers and spill kits get checked monthly, not just when a surprise visit looms. OSHA guidelines and plant rules aren’t just paperwork—they keep people out of the ER.

I can’t count the number of shortcuts that end up as horror stories. Waste gets handled as hazardous material every time—never down the drain, never mixed with organics that can react. Labeling makes a difference, so containers stay marked and records stay clean. Environmental rules exist for a reason; ignoring them brings fines and sometimes lasting harm to water or wildlife.

Cutting corners can mean burns, lost time, or worse. Respect for the chemical and a focus on training and checks beat bravado or speed. The right gloves, goggles, hoods, and sober procedure give everyone in the lab their shot at going home healthy, every shift.

In the world of organic chemistry, it doesn’t take long before you run into molecules built on the backbone of benzene. Diisopropylbenzene stands out for more than its tongue-twisting name. The formula looks straightforward: C12H18. The name clues us in: two isopropyl groups connecting to a benzene ring. The structure resembles a classic aromatic ring with two branches sticking out, each branch shaped like a “Y” thanks to isopropyl’s (C3H7) setup.

Diisopropylbenzene doesn’t come as a one-size-fits-all. It shows up as three isomers: 1,2-; 1,3-; and 1,4-diisopropylbenzene. The numbers show where those isopropyl arms attach on the ring. In the 1,4- (or para-) version, the two isopropyls stretch out opposite each other. This version comes up the most in industrial work, though the 1,2- (ortho-) and 1,3- (meta-) types also have their roles.

In my own experience with industrial raw materials, para-diisopropylbenzene takes the lead in manufacturing antioxidants. Here, it’s more than a simple chemical—it sets the stage for turning into hydroquinone and catechol. Both phenolic compounds come out swinging as stabilizers, playing defense for plastics, rubbers, and even food packaging. Without this backbone, whole industries would risk product breakdown and loss.

Working near lab benches, you feel the significance of each structure. Many projects pivoted around how certain places on the ring allowed for specific reactions. The 1,4-isomer’s symmetry streamlines transformations, creating less waste and reducing separation headaches. So, plant managers and lab chemists put their money on this isomer. Its structure just fits better into large-scale syntheses, cutting costs and boosting yields—two things every manufacturer notices at the year’s end.

With benefits, concerns follow. Benzene-based compounds bring more than a list of uses—they pose safety and environmental questions. Long-term exposure to aromatic hydrocarbons, through either the vapor or skin contact, raises health concerns. The EPA lists both environmental and health impacts, pushing operators to adopt closed systems. From my time assisting on chemical safety audits, I’ve watched teams review containment measures around aromatic compounds, always tracking leaks and spill management protocols.

The journey from lab to landfill or waterways marks another critical stage. Benzene rings hold up against natural breakdown. Plants and chemical companies turn to high-efficiency incinerators and advanced filtration to trap and neutralize compounds before discharge. Adopting solvent recycling further reduces environmental loads. I have seen facilities overhaul their procedures to win regulatory approval—investing in training, better ventilation, and smarter waste streams. It’s a story of ongoing checks, not just for corporate image but for long-term sustainability and real-world safety.

With more regulatory spotlight on aromatic hydrocarbons, demand for alternative, greener syntheses rises. Finding replacements with fewer health and environmental concerns strengthens both industry and community trust. Boosting R&D investment gives young chemists and process engineers a say in how tomorrow’s chemicals get made—and how those molecules should behave once they live out their usefulness.

People don't always think about chemicals unless they work with them. Yet some of these liquids can cause a lot of trouble if overlooked, and diisopropylbenzene stands out for a few reasons. I've seen what happens when folks treat it the same as paint thinner or just toss it in the corner of a storeroom. The fumes build up, the container gets grimy, and everyone takes a risk that isn't worth it. Keeping this material stored the right way cuts down not only fire hazards but also keeps everyone a bit safer at the end of the day.

Diisopropylbenzene burns like a torch if ignited. The stuff is volatile, and its vapors don't take much to catch a spark and set off a chain reaction. Sometimes, people forget that these vapors can travel farther than you’d guess, hugging the floor and slipping under closed doors. Scientists and safety officers have flagged it not only for flammability but also for possible health risks when inhaled. If a person starts breathing too much of those vapors, headaches and nausea often follow.

Best results come from storing this chemical away from direct sunlight and heat sources. A cool, shady spot makes sense, ideally where the air moves around a bit. Flammable storage cabinets, those painted yellow with the chunky handles, offer solid protection—especially because their seals limit fumes escaping. Containers should always stay tightly closed when not in use. I remember a coworker saying, "A loose lid is just asking for trouble," and he was right. An open drum means fumes can escape, and the risk grows every hour.

Keep water and oxidizing agents far away. If the containers leak or get punctured, reacting with the wrong material can spur on fires or create toxic byproducts. Sturdy, leakproof containers made specifically for flammable chemicals work best. Labels must remain readable; if they're torn or faded, it's worth replacing them right away. Emergency responders depend on clear labels if something goes wrong.

Chemical storage isn’t a set-and-forget job. I’ve walked through countless storage areas and seen containers past their prime—rusty metal, dented drums, sticky surfaces from leaking product. Schedule routine checks, looking for signs of container damage or spills. If something doesn’t look right, moving the chemical to a fresh container can head off disaster. Keep an eye on ventilation systems too. Poor airflow lets vapors build up.

Giving people the right information saves headaches in the long run. Workers must know why these chemicals act the way they do and how to handle emergencies. Training sessions shouldn't just tick boxes—they need to stick. Going over real stories from accidents makes the lessons land better. Gloves, goggles, and flame-resistant coats all play a role too, even for brief tasks.

Spill kits, fire extinguishers, and easy-to-read safety data sheets should always be close. If a container tips or a leak starts, acting fast stops small problems from spreading. Fire suppression systems, especially in bigger storage areas, add peace of mind. Invest in these basics before problems start—they'll pay off with less downtime and safer staff.

Diisopropylbenzene rarely pops up in everyday conversation, but it shows up behind the scenes in chemical plants, labs, and some manufacturing circles. This compound has a habit of flying below the public’s radar because most folks don’t come across it in their kitchens or garages. Still, what happens in those factories and labs inevitably leaks out into the wider world—sometimes literally. And that’s where the risks start to show up, both for health and for the planet.

I’ve worked alongside techs in an industrial lab, and the way they treat aromatic hydrocarbons always stuck with me. Diisopropylbenzene belongs to that family, which includes some notorious cousins like benzene and toluene. Workers always suited up with gloves, goggles, and masks. Not because someone told them to—because they’d seen what careless handling could do. Inhalation irritated throats, accidental skin contact caused redness. Folks who ignored the rules sometimes ended up with headaches or felt dizzy on the job. Chronic exposure, even at low levels, leaves open questions. Regulatory agencies don’t class this stuff as a major toxin, but long-term studies remain thin. It isn’t wise to shrug off unknowns, especially given how similar chemicals have caused trouble in the past.

The harder truth comes from looking at inhalation and skin contact. The body doesn’t process these hydrocarbons kindly. Using the clever tactic of engineering controls—vent hoods, sealed systems, quick cleanups—doesn’t always shield everyone perfectly. I’ve seen friends lose time to minor but real symptoms because safety routines slipped. Even off the clock, taking home traces on boots or clothes can expose family members. So even if the big headlines about acute toxicity haven’t landed yet, the discipline around safe handling speaks volumes.

Factories don’t run in sealed bubbles. Waste from chemical processing, including compounds like diisopropylbenzene, finds its way into local landfills, sewers, or water systems. Several times, I’ve spotted spill reports buried in environmental bulletins. Cleanup crews hustle to sweep up leaks, but groundwater and soil stick around long after the parade moves on. Diisopropylbenzene breaks down quicker than many persistent pollutants, but it’s not harmless while it lingers. Fish and insects in those waterways aren’t just numbers—they’re part of the bigger web that eventually circles back to us. In lab research, diisopropylbenzene has shown mild toxicity to aquatic life. That line between “mild” and “serious” blurs over years of routine disposal or overlooked leaks.

Every industry tries to keep hazards wrapped up tight, but low-level releases and workplace exposures persist. Honest answers start with aiming higher on containment and personal protection. Wearing gloves and masks isn’t enough if waste management is an afterthought. Closed-loop systems cut spills before they start. Quick cleanup procedures stop the domino effect. Every time an operation reuses or destroys this chemical instead of dumping it, risk drops for everybody—workers, neighbors, pets, and wildlife.

From a broader community perspective, public reporting on spills and disposal practices builds trust. Regulators and plant managers can open the books and let communities push for better air and water monitoring. The more people understand how chemicals flow through their backyard, the less mysterious—or risky—compounds like diisopropylbenzene become. Maybe that honesty will stop future headaches before they start.

| Names | |

| Preferred IUPAC name | 1,3-Diisopropylbenzene |

| Other names |

1,3-Diisopropylbenzene m-Diisopropylbenzene m-DIPB |

| Pronunciation | /daɪˌaɪsəˌproʊpəlˈbɛnziːn/ |

| Identifiers | |

| CAS Number | 25321-09-9 |

| 3D model (JSmol) | ``` /* JSmol model data for Diisopropylbenzene */ CC(C)C1=CC=CC=C1C(C)C ``` |

| Beilstein Reference | 1362097 |

| ChEBI | CHEBI:34693 |

| ChEMBL | CHEMBL155594 |

| ChemSpider | 7737 |

| DrugBank | DB03437 |

| ECHA InfoCard | ECHA InfoCard: 100.066.797 |

| EC Number | 201-253-7 |

| Gmelin Reference | 143892 |

| KEGG | C06736 |

| MeSH | D005874 |

| PubChem CID | 8449 |

| RTECS number | GO3140000 |

| UNII | OAY9DU3LH2 |

| UN number | UN2352 |

| Properties | |

| Chemical formula | C12H18 |

| Molar mass | 162.27 g/mol |

| Appearance | Colorless liquid |

| Odor | aromatic |

| Density | 0.863 g/cm3 |

| Solubility in water | Insoluble |

| log P | 3.9 |

| Vapor pressure | 0.17 mmHg (25°C) |

| Acidity (pKa) | 18.7 |

| Basicity (pKb) | na |

| Magnetic susceptibility (χ) | -74.0×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.4900 |

| Viscosity | 1.66 cP (25 °C) |

| Dipole moment | 1.63 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 273.7 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -71.9 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -7264.6 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H226, H315, H319, H335 |

| Precautionary statements | P210, P261, P273, P301+P310, P331, P303+P361+P353, P305+P351+P338, P405, P501 |

| Flash point | 124°C |

| Autoignition temperature | 457 °C (855 °F; 730 K) |

| Explosive limits | 1% - 5% |

| Lethal dose or concentration | LD50 (oral, rat): 3300 mg/kg |

| LD50 (median dose) | LD50 (median dose): 3000 mg/kg (rat, oral) |

| NIOSH | SN40700 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for diisopropylbenzene: Not established by OSHA. |

| REL (Recommended) | 5 ppm |

| IDLH (Immediate danger) | 300 ppm |

| Related compounds | |

| Related compounds |

Benzene Cumene 1,3,5-Triisopropylbenzene Tetraisopropylbenzene Isopropylbenzene |